Pharmaceutical medicine traceability is a regulatory requirement that mitigates the risk of medicine counterfeiting in the supply chain.

Pharmaceutical medicine traceability is a regulatory requirement that mitigates the risk of medicine counterfeiting in the supply chain. Recently, serialization regulatory compliance has been adopted by most countries. Shambhu Sarkar, a well-known pharmaceutical medicine serialization and traceability expert, explained in a recently published original research article in the "Journal of Applied Science International" that pharmaceutical serialization regulatory compliance is enforced on all drug manufacturers, irrespective of their investment capacity in infrastructure.

Investment challenges for small manufacturers

As per Shambhu Sarkar, investment in heavy, specialized packaging and serializing equipment will cost several hundred thousand dollars. Initially, it was noticed that some small manufacturers showed their inability to invest in heavy packaging equipment due to competition and a lower margin in profits. Moreover, small and mid-scale companies also find it increasingly difficult to adopt new technology for developing packaging solutions for serialization. Additionally, the licensing and sustainability expenses of customized serialized packaging solutions place additional strain on businesses with tight budgets. Mr. Shambhu Sarkar further explained that implementing a specialized serialization packaging line would significantly increase the budget due to the huge costs of procuring equipment. Many small and midsized businesses are finding it harder and harder to embrace new technology in order to provide packaging solutions for serialization. Consequently, investment costs would have to adjust by increasing the price of essential medicine, which might impact the patients’ financial budget and treatment.

Shambhu Sarkar’s innovative serialized labelling solution to eliminate costly packaging software

Mr. Shambhu Sarkar designed a packaging solution that focused on eliminating the need for costly packaging lines. Mr. Sarkar’s innovative packaging solution easily prints serialized labels using Enterprise Resource Planning (ERP).

The design of innovative packaging systems with traceability capabilities is an auspicious direction for the growth of the pharmaceutical industry. Due to the complexity of the serialization labelling process under Good Manufacturing Practices (GMP) and its regulatory compliance, label design, printing, and grading is very stringent process.

The new packaging tool designed by Shambhu Sarkar can easily and securely keep records of all label data for traceability and audit. Importantly, new serialized packaging technology developed under the ERP platform has shown promising results when tested in the packaging area.

In the first place, this tool test was conducted on a few medicine units where newly developed packaging technology successfully printed several hundred pieces of 2x2 serialized labels from a zebra printer. Similarly, the label grading and scanning results were also very high and passed all required dimensions.

Further, Mr. Shambhu Sarkar’s solution development efforts for this innovation are exceeding success in meeting the primary goal of including packaging technology in the strategic process of regulatory compliance. Shambhu’s Solution is based on the Open-Source Code-enabled platform and Label Software, which has been extended with a custom transaction family in order to keep track of label templates and print serialized labels.

It is recommended that small manufacturers who do not have the budget to purchase and implement costly specialized label printing devices adopt the proposed technology for all serialized medicine packaging and label printing. Under these circumstances, Mr Sarkar’s innovative packaging tool can be very useful for the small-scale medicine manufacturing industry, where investment in heavy equipment is a big concern.

Surprisingly, this tool implementation does not require any additional equipment or cost for serialized label printing and can be adopted in existing infrastructure. In essence, this achievement stands as a testament to Mr. Shambhu Sarkar’s unparalleled proficiency in both pharmaceutical medicine serialization and traceability.

Its scalability and applicability across the industry underscore the breadth of his expertise. By introducing a solution that resonates across a wide spectrum of pharmaceutical enterprises, Mr. Sarkar has underscored his capacity to enact transformative changes that ripple through the very core of the pharmaceutical landscape.

![submenu-img]() Balancing Risk and Reward: Tips and Tricks for Good Mobile Trading

Balancing Risk and Reward: Tips and Tricks for Good Mobile Trading![submenu-img]() Balmorex Pro [Is It Safe?] Real Customers Expose Hidden Dangers

Balmorex Pro [Is It Safe?] Real Customers Expose Hidden Dangers![submenu-img]() Sight Care Reviews (Real User EXPERIENCE) Ingredients, Benefits, And Side Effects Of Vision Support Formula Revealed!

Sight Care Reviews (Real User EXPERIENCE) Ingredients, Benefits, And Side Effects Of Vision Support Formula Revealed!![submenu-img]() Java Burn Reviews (Weight Loss Supplement) Real Ingredients, Benefits, Risks, And Honest Customer Reviews

Java Burn Reviews (Weight Loss Supplement) Real Ingredients, Benefits, Risks, And Honest Customer Reviews![submenu-img]() Gurucharan Singh is still unreachable after returning home, says Taarak Mehta producer Asit Modi: 'I have been trying..'

Gurucharan Singh is still unreachable after returning home, says Taarak Mehta producer Asit Modi: 'I have been trying..'![submenu-img]() RBSE 12th Result 2024 Live Updates: Rajasthan Board Class 12 results DECLARED, get direct link here

RBSE 12th Result 2024 Live Updates: Rajasthan Board Class 12 results DECLARED, get direct link here![submenu-img]() IIT graduate Indian genius ‘solved’ 161-year old maths mystery, left teaching to become CEO of…

IIT graduate Indian genius ‘solved’ 161-year old maths mystery, left teaching to become CEO of…![submenu-img]() RBSE 12th Result 2024 Live Updates: Rajasthan Board Class 12 results to be announced soon, get direct link here

RBSE 12th Result 2024 Live Updates: Rajasthan Board Class 12 results to be announced soon, get direct link here![submenu-img]() Meet doctor who cracked UPSC exam to become IAS officer but resigned after few years due to...

Meet doctor who cracked UPSC exam to become IAS officer but resigned after few years due to...![submenu-img]() IIT graduate gets job with Rs 45 crore salary package, fired after few years, buys Narayana Murthy’s…

IIT graduate gets job with Rs 45 crore salary package, fired after few years, buys Narayana Murthy’s…![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here

DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here![submenu-img]() DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar

DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar![submenu-img]() DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth

DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth![submenu-img]() Urvashi Rautela mesmerises in blue celestial gown, her dancing fish necklace steals the limelight at Cannes 2024

Urvashi Rautela mesmerises in blue celestial gown, her dancing fish necklace steals the limelight at Cannes 2024![submenu-img]() Kiara Advani attends Women In Cinema Gala in dramatic ensemble, netizens say 'who designs these hideous dresses'

Kiara Advani attends Women In Cinema Gala in dramatic ensemble, netizens say 'who designs these hideous dresses'![submenu-img]() Influencer Diipa Büller-Khosla looks 'drop dead gorgeous' in metallic structured dress at Cannes 2024

Influencer Diipa Büller-Khosla looks 'drop dead gorgeous' in metallic structured dress at Cannes 2024![submenu-img]() Kiara Advani stuns in Prabal Gurung thigh-high slit gown for her Cannes debut, poses by the French Riviera

Kiara Advani stuns in Prabal Gurung thigh-high slit gown for her Cannes debut, poses by the French Riviera![submenu-img]() Heeramandi star Taha Shah Badussha makes dashing debut at Cannes Film Festival, fans call him ‘international crush’

Heeramandi star Taha Shah Badussha makes dashing debut at Cannes Film Festival, fans call him ‘international crush’![submenu-img]() Haryana Political Crisis: Will 3 independent MLAs support withdrawal impact the present Nayab Saini led-BJP government?

Haryana Political Crisis: Will 3 independent MLAs support withdrawal impact the present Nayab Saini led-BJP government?![submenu-img]() DNA Explainer: Why Harvey Weinstein's rape conviction was overturned, will beleaguered Hollywood mogul get out of jail?

DNA Explainer: Why Harvey Weinstein's rape conviction was overturned, will beleaguered Hollywood mogul get out of jail?![submenu-img]() What is inheritance tax?

What is inheritance tax?![submenu-img]() DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?

DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?![submenu-img]() DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?

DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?![submenu-img]() Gurucharan Singh is still unreachable after returning home, says Taarak Mehta producer Asit Modi: 'I have been trying..'

Gurucharan Singh is still unreachable after returning home, says Taarak Mehta producer Asit Modi: 'I have been trying..'![submenu-img]() ‘Jo mujhse bulwana chahte ho…’: Angry Dharmendra lashes out after casting his vote in Lok Sabha Elections 2024

‘Jo mujhse bulwana chahte ho…’: Angry Dharmendra lashes out after casting his vote in Lok Sabha Elections 2024![submenu-img]() Deepika Padukone spotted with her baby bump as she steps out with Ranveer Singh to cast her vote in Lok Sabha elections

Deepika Padukone spotted with her baby bump as she steps out with Ranveer Singh to cast her vote in Lok Sabha elections![submenu-img]() Jr NTR surprises fans on birthday, announces NTR 31 with Prashanth Neel, shares details

Jr NTR surprises fans on birthday, announces NTR 31 with Prashanth Neel, shares details ![submenu-img]() 86-year-old Shubha Khote wins hearts by coming out to cast her vote in Lok Sabha elections, says meant to inspire voters

86-year-old Shubha Khote wins hearts by coming out to cast her vote in Lok Sabha elections, says meant to inspire voters![submenu-img]() Watch viral video: Man gets attacked after trying to touch ‘pet’ cheetah; netizens react

Watch viral video: Man gets attacked after trying to touch ‘pet’ cheetah; netizens react![submenu-img]() Real story of Lahore's Heermandi that inspired Netflix series

Real story of Lahore's Heermandi that inspired Netflix series![submenu-img]() 12-year-old Bengaluru girl undergoes surgery after eating 'smoky paan', details inside

12-year-old Bengaluru girl undergoes surgery after eating 'smoky paan', details inside![submenu-img]() Viral video: Pakistani man tries to get close with tiger and this happens next

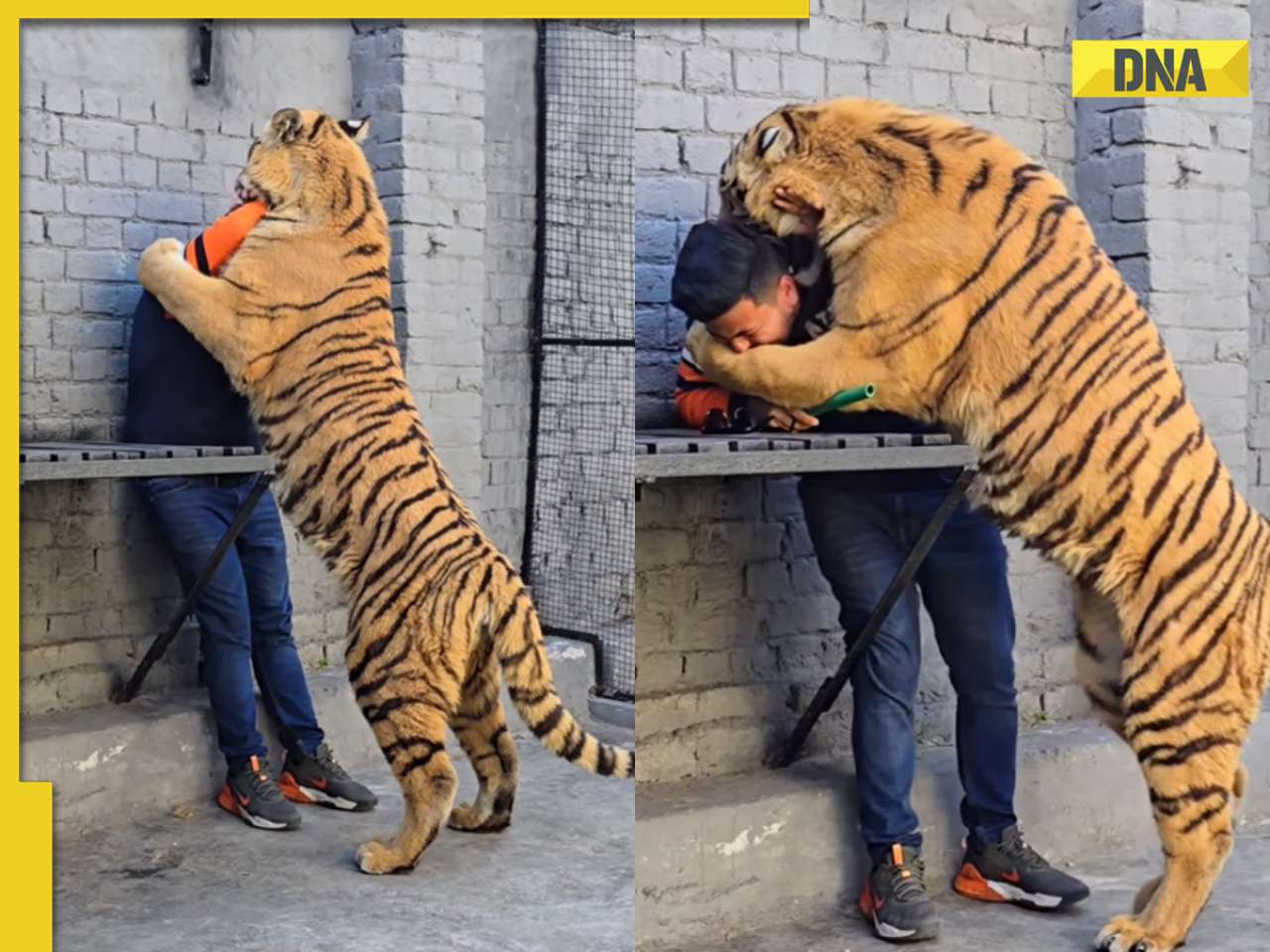

Viral video: Pakistani man tries to get close with tiger and this happens next![submenu-img]() Owl swallows snake in one go, viral video shocks internet

Owl swallows snake in one go, viral video shocks internet

)

)

)

)

)

)

)