TSMC said that Indian presence will enable it to service its US clients who are increasingly depending on Indian design firms.

HYDERABAD: The finance and the IT ministries may be fighting over the SEZ incentives on the impending semiconductor policy, but two things that happened last week bode well for the industry.

Taiwan Semiconductor Manufacturing Co (TSMC), the world’s largest semiconductor foundry, opened its office in India. Then India’s very own, albeit yet-to-be-born foundry, SemIndia, went and acquired Bangalore-based design firm Exalted Networks.

Though not necessarily huge in monetary terms, the two developments coinciding with the India Semiconductor Association’s (ISA) Vision Summit here, nevertheless, point to the country’s emergence as a semiconductor design power house.

Perhaps, it also heralds India’s entry into the exalted space of semiconductor manufacture in a significant way in the not-too-distant future.

TSMC, which reported Q4FY06 sales of $2.5 billion, said the Indian presence will enable it to service its US clients who are increasingly depending on Indian design firms.

According to industry sources, TSMC was also perhaps testing waters to get into manufacturing in India later. SemIndia, with its acquisition, signalled a whole new business model aimed at a presence in every segment of the semiconductor food-chain — testing and packaging to fabrication of silicon wafers, leveraged on India’s design strengths.

Very Large Scale Integration and embedded design business, the core bread earner for the Indian fabless semiconductor industry, estimated at just $3.25 billion in 2005, is projected to reach $14.42 billion in 2010 and $43.07 billion in 2015 at a CAGR of 30%. Employment in the sector will increase from 74,850 to nearly 8,00,000 in 2015, an earlier study by Frost & Sullivan for the ISA projected.

Encouraging while the potential seems to be, there was a word of caution, too, at the two-day seminar.

India may be on the threshold of charting out a new future in the semiconductor landscape. But it is time the industry did something about the quality of manpower, pointed out a benchmarking survey of the Indian design capabilities with nine other countries.

ISA-Ernst & Young Benchmarking Study: India in the Global Semiconductor Design Ecosystem, released at the conference, clearly demonstrated the country’s core strengths in the current availability and future scalability and cost of its talent. Quality of the manpower, however, was a cause for concern.

The ISA-E&Y study benchmarks India against seven other countries on 10 parameters for evaluating the choice of design centre locations by the global semiconductor industry.

Interestingly, respondents ranked India the fourth among the 10 countries on manpower quality and fifth on quality of technical education on a scale of 1 to 10.

But China, which is rated as well as India on talent cost and second on availability and scalability, the survey pointed out, could pose a challenge to India’s ambitions of becoming a dominant player in the semiconductor design sector.

“For the first time, the industry has authentic information on which corporates can peg their business decisions”, Poornima Shenoy, president, ISA, said, adding the country has the necessary strengths to take on the mantle with the concerted efforts by the stakeholders, the industry, academy and government.

While the need for action on the design front was clear, caution was sounded on the manufacturing front, too, with experts questioning if India was ready for the latest generation semiconductor fabrication, and whether it needed a presence in the foundry business at all.

Going by the global trends, where even the big guys are exiting latest generation .90 nanometre and .45 nanometre technologies, India should perhaps tread cautiously, warned senior Gartner analyst Bryan Lewis, kicking off a debate if the country needs a fab at all.

However, compelling strategic reasons and domestic economics make domestic fabs more than attractive. While the government itself is going for an upgrade of some of its fabs for strategic reasons, domestic consumption of electronics equipment, projected to be 11% of the global output at $363 billion by 2015, is an attraction.

According to the ISA-F&S report, an estimated manufacturing of $155 billion in 2015 is expected to create an opportunity of $15.52 billion for semiconductor companies and electronic manufacturing services (EMS) companies. And not all of these market segments will need state-of-the-art .90 mciron and lower chips, point out companies wanting to set up fabs in India.

Clearly, the concerns notwithstanding, the Indian semiconductor sector seems to be getting its act together to play a bigger role in the global semiconductor space. The impending semiconductor policy is expected to give the necessary fillip for this with an incentive regime for all semiconductor based manufacturing.

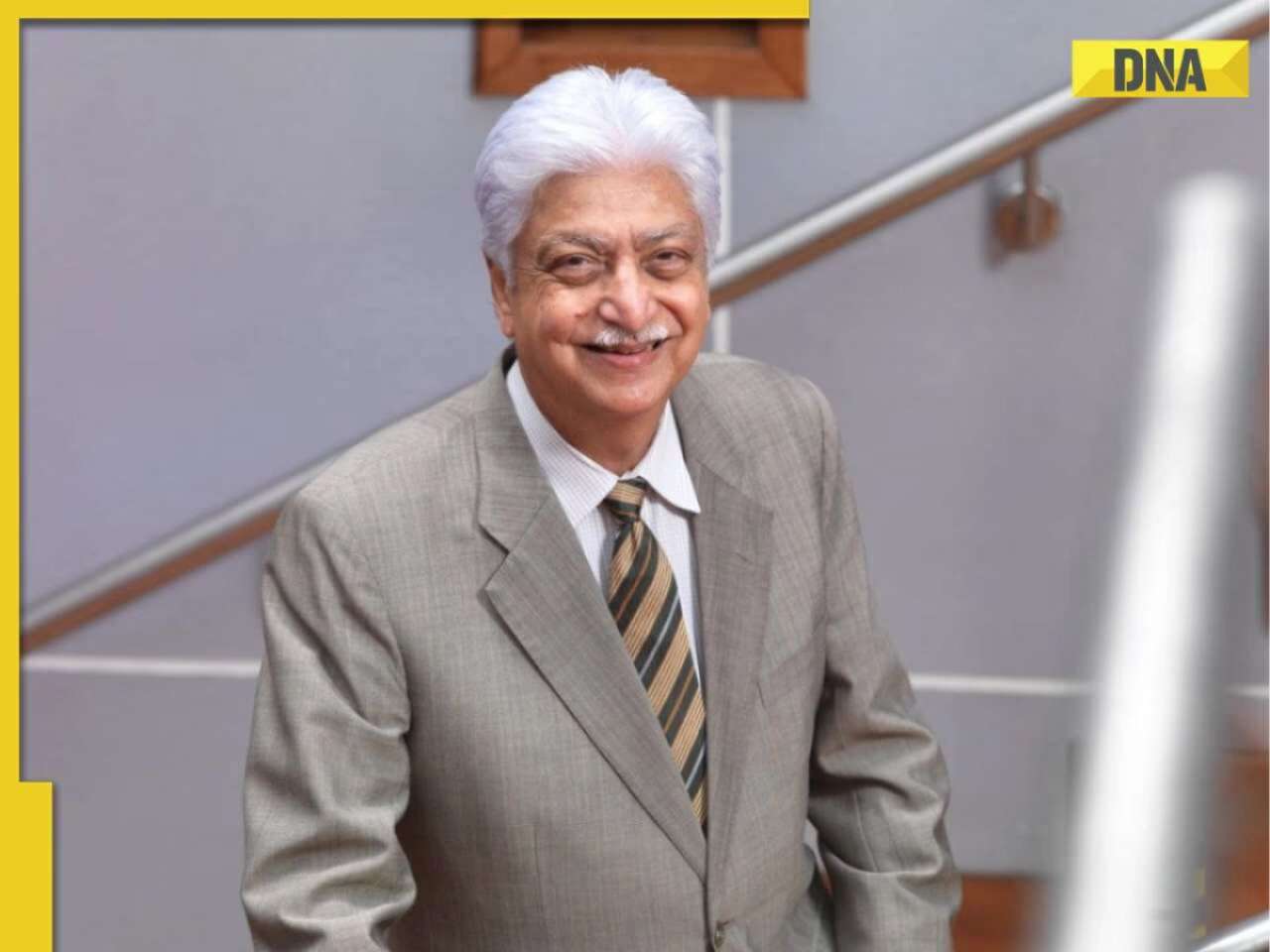

![submenu-img]() Azim Premji may acquire majority stake in this bank from…

Azim Premji may acquire majority stake in this bank from…![submenu-img]() Meet schoolmates who quit high-paying jobs to start their own business, invested Rs 1 lakh, now worth Rs…

Meet schoolmates who quit high-paying jobs to start their own business, invested Rs 1 lakh, now worth Rs…![submenu-img]() Meet daughter of cleaning contractor who cleared UPSC exam in first attempt, secured AIR...

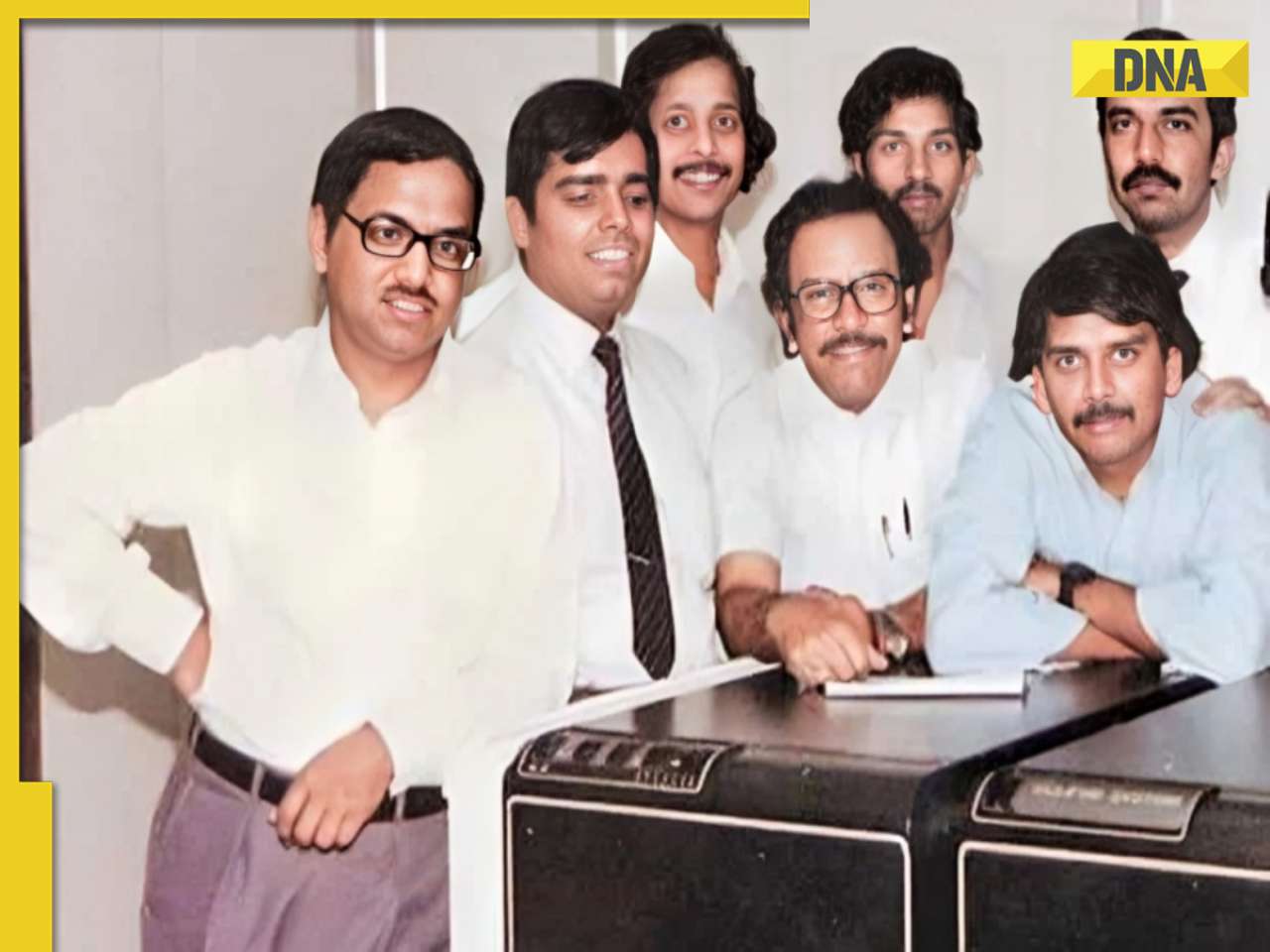

Meet daughter of cleaning contractor who cleared UPSC exam in first attempt, secured AIR...![submenu-img]() Meet man who was first employee of Infosys, it's not Narayana Murthy, Nandan Nilekani, SD Shibulal

Meet man who was first employee of Infosys, it's not Narayana Murthy, Nandan Nilekani, SD Shibulal![submenu-img]() Sobhita Dhulipala opens up about facing ‘casual objectification’: ‘I have been told so many times to…’

Sobhita Dhulipala opens up about facing ‘casual objectification’: ‘I have been told so many times to…’![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here

DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here![submenu-img]() DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar

DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar![submenu-img]() DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth

DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth![submenu-img]() Streaming This Week: Heeramandi, Shaitaan, Manjummel Boys, latest OTT releases to binge-watch

Streaming This Week: Heeramandi, Shaitaan, Manjummel Boys, latest OTT releases to binge-watch![submenu-img]() Remember Ayesha Kapur? Michelle from Black, here's how actress, nutrition coach, entrepreneur looks after 19 years

Remember Ayesha Kapur? Michelle from Black, here's how actress, nutrition coach, entrepreneur looks after 19 years![submenu-img]() Remember Heyy Babyy's cute 'Angel' Juanna Sanghvi? 20 year-old looks unrecognisable now, fans say 'her comeback will...'

Remember Heyy Babyy's cute 'Angel' Juanna Sanghvi? 20 year-old looks unrecognisable now, fans say 'her comeback will...'![submenu-img]() In pics: Arti Singh stuns in red lehenga as she ties the knot with beau Dipak Chauhan in dreamy wedding

In pics: Arti Singh stuns in red lehenga as she ties the knot with beau Dipak Chauhan in dreamy wedding![submenu-img]() Actors who died due to cosmetic surgeries

Actors who died due to cosmetic surgeries![submenu-img]() DNA Explainer: Why Harvey Weinstein's rape conviction was overturned, will beleaguered Hollywood mogul get out of jail?

DNA Explainer: Why Harvey Weinstein's rape conviction was overturned, will beleaguered Hollywood mogul get out of jail?![submenu-img]() What is inheritance tax?

What is inheritance tax?![submenu-img]() DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?

DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?![submenu-img]() DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?

DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?![submenu-img]() DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence

DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence![submenu-img]() Sobhita Dhulipala opens up about facing ‘casual objectification’: ‘I have been told so many times to…’

Sobhita Dhulipala opens up about facing ‘casual objectification’: ‘I have been told so many times to…’![submenu-img]() Meet actress, who debuted with Aamir Khan's film, now winning hearts in Heeramandi; know her connection to Preity Zinta

Meet actress, who debuted with Aamir Khan's film, now winning hearts in Heeramandi; know her connection to Preity Zinta![submenu-img]() Meet engineer-turned-actor, who quit high-paying job for acting, struggled to get Rs 200; became superstar, now earns…

Meet engineer-turned-actor, who quit high-paying job for acting, struggled to get Rs 200; became superstar, now earns… ![submenu-img]() This film bombed at box office, earned less than Rs 2 crore, Shraddha Kapoor was first choice, director quit filmmaking

This film bombed at box office, earned less than Rs 2 crore, Shraddha Kapoor was first choice, director quit filmmaking![submenu-img]() India's biggest flop lost Rs 250 crore, derailed 2 stars; worse than Adipurush, Shamshera, Ganapath, Laal Singh Chaddha

India's biggest flop lost Rs 250 crore, derailed 2 stars; worse than Adipurush, Shamshera, Ganapath, Laal Singh Chaddha![submenu-img]() IPL 2024: Venkatesh Iyer, Mitchell Starc power Kolkata Knight Riders to 24-run win over Mumbai Indians

IPL 2024: Venkatesh Iyer, Mitchell Starc power Kolkata Knight Riders to 24-run win over Mumbai Indians![submenu-img]() RCB vs GT IPL 2024: Predicted playing XI, live streaming details, weather and pitch report

RCB vs GT IPL 2024: Predicted playing XI, live streaming details, weather and pitch report![submenu-img]() RCB vs GT IPL 2024 Dream11 prediction: Fantasy cricket tips for Royal Challengers Bengaluru vs Gujarat Titans

RCB vs GT IPL 2024 Dream11 prediction: Fantasy cricket tips for Royal Challengers Bengaluru vs Gujarat Titans![submenu-img]() Australia dethrone India to become No. 1 ranked test team after annual rankings update

Australia dethrone India to become No. 1 ranked test team after annual rankings update![submenu-img]() Watch: MS Dhoni's heartfelt gesture for CSK's 103-yr-old superfan wins internet, video goes viral

Watch: MS Dhoni's heartfelt gesture for CSK's 103-yr-old superfan wins internet, video goes viral![submenu-img]() Viral video: Man transports huge wardrobe on bike, internet is stunned

Viral video: Man transports huge wardrobe on bike, internet is stunned![submenu-img]() Mother polar bear cuddles with her cub, viral video will melt your heart

Mother polar bear cuddles with her cub, viral video will melt your heart![submenu-img]() Viral video: Girl's 'Choli Ke Piche' dance performance at college fest divides internet, watch

Viral video: Girl's 'Choli Ke Piche' dance performance at college fest divides internet, watch![submenu-img]() Video: Cobra mother's protective instincts go viral as she guards nest of eggs, watch

Video: Cobra mother's protective instincts go viral as she guards nest of eggs, watch![submenu-img]() Die-hard Virat Kohli fan displays love for 'Namma RCB' at graduation ceremony in US, video goes viral

Die-hard Virat Kohli fan displays love for 'Namma RCB' at graduation ceremony in US, video goes viral

)

)

)

)

)

)