Raghupati Singhania, chairman and managing director, JK Tyre speaks about a wide range of topics and challenges, including the threat from the dumping of Chinese products. He also talked about the company's interest in getting into the civil aviation sector.

JK Tyre & Industries Ltd, part of the Rs 28,000 crore JK Group last week rolled out its 10 millionth radial tyre from its Vikrant plant at Mysuru in Karnataka. The company, which ranks amongst the top 25 tyre manufacturers in the world and has a wide range of products catering to diverse business segments in the automobile industry, at present operates 12 plants - nine in India and three in Mexico. It recently announced integrating its Research and Development centres (R&D) spread across different locations in the country into one by setting up a Rs 100 crore centre in Mysuru.

Raghupati Singhania, chairman and managing director, JK Tyre, in an interview with Shahkar Abidi, speaks about a wide range of topics and challenges, including the threat from the dumping of Chinese products in the Indian market. He also talked about the company's interest in getting into the civil aviation sector which provides huge scope for growth as India is amongst the fastest-growing aviation markets in the world.

Q. Indian tyre manufacturing industry has been constantly lobbying against the dumping of Chinese products. As an industry leader, don't you think the Indian companies are playing the game with a protectionist attitude?

A. Dumping of China-made tyres is a severe problem engulfing the Indian tyre market and has been increasing with each passing day. Last year there has been more than 50% increase in the Chinese tyre dumping in the Indian market. We as an industry are not against competition but are against the dumping which is being done by playing the price factor as Chinese tyres are about 25-30% cheaper than the Indian ones. In some instances, they can be even 40% cheaper. What we want is just a level playing field. The Indian companies cannot compete with them on price. Also, the end loser is definitely the consumer as what he/she gets is poor quality tyres and a bad driving experience. Also, I would like to point here that it is not that once the anti-dumping measures are out the dumping of Chinese tyres will come down to zero. No, it does not happen that way.

According to me, there will about 15% change as there are many companies which import tyres from China, put their branding and sell it in the Indian market. Therefore, as an industry, we are taking lots of efforts on our part to face the problem and see through the tide. At an individual company level, we have tried to address the issue to some extent. We have come out with solutions. We came out with 'pay per kilometre model' wherein the fleet companies pay us only based on the number of hours the tyres are used. We have tied up with three large fleet operators for it, but I can't name them. At the collective level, we have also approached the central government to intervene and stop the dumping of Chinese tyres. It has been over 16 months but so far we have not seen much action on the ground by the government. In contrast, it takes just 45 days to complete the same process in a country like the US.

Q. Rubber shortage has been another problem for a while. How is the situation at present?

A. The situation of rubber availability has gone from bad to worse in recent times. The duties have increased from 22% earlier to 25% at present, which has definitely upped the cost of procurement. Also, the price of rubber has increased, putting a severe strain on the production cost of the end product . This year, about 40% of rubber had to be imported as against 30% last year as imports are cheaper due to the shortage of it in the local market. Nobody wants to import willfully, but then we can't close our plants for the unavailability of rubber and something has to be done about it.

Q. How is JK Tyre performing in supplies to the defence sector?

A. We are the biggest supplier of tyres to the defence sector including the already placed orders and with the opening of the defence sector, it is set to improve further. However, the demand in the defence sector is not like other verticals. It is need based as the department first takes a stock of their requirement from time to time and then comes up with tenders for its procurement.

Q. A lot of Indian companies are getting into the aviation market by offering to supply parts to aircraft manufacturers. Does JK Tyre have any plans to get into the aviation segment?

A. Yes, we are working towards that direction as it's a very lucrative segment. Though at present I cannot comment more on it as plans are still being worked out and things are still taking shape. But one thing is sure - we cannot ignore the segment as its going very strong and offers a lot of opportunity for growth.

Q. How much investment has been made so far by JK Tyre?

A. In the last quarter, we completed the second phase of construction of a plant at Chennai with a total investment of Rs 1,430 crore. The plant makes truck and car radials. It has a production capacity of 12 lakh TBRs (truck / bus radials) and 45 lakh PCRs (passenger car radials). The plant has a blueprint of scaling up to 2 million truck radials and 10 million PCRs. Similarly, around Rs 2,200 crore has been invested for the acquisition of Cavendish Industries which houses three tyre business undertakings of Birla Tyres. The plants located at Laksar in Haridwar produced a range of products including tyres, tubes and flaps. With the acquisition, we have entered into the high growth segment of 2-wheeler and 3-wheeler tyres. Similarly, JK Tyre took over the state-owned Vikrant plant and turned it around into a state-of-the-art plant with an investment of over Rs 1,200 crore . Today, we have 12 plants globally with a future ready capacity of 350 lakh tyres per annum. Also, the capacity of the Mexico plants is under expansion. The capacity is expected to go up to 5 million tyres from the existing 3.5 million units per year.

Q. What will be your new R&D facility in Mysuru like and how is it going to further the purpose of JK Tyre?

A. We strongly believe that technology is the backbone of our growth, and therefore, JK Tyre has invested heavily in research and development as well as product development infrastructure. This helps us to remain ahead in the marketplace as tyre technology is ever-evolving and developing rapidly. Apart from the product and process, we have also been deploying latest technology in every aspect of our business, be it manufacturing, logistics, sales and outreach to customers. We take R&D at several locations. With growth in mind, we were planning our next move and realised that disintegrated approach is not a nice idea. Therefore, we decided to combine all such centres under one roof in Mysuru. The new structure will occupy an area of 1 lakh square feet and will be made at the cost of Rs 100 crore plus, and will have the most modern and advanced equipment and a large pool of engineer and scientists. It will initially have about 200 engineers and scientists with the number doubling by next year. Some of the equipment that we are bringing in for this centre is latest state-of-the-art and not available in the country, even in the auto manufacturing companies. The challenges in tyre and auto industry technology are increasing with each passing day and all the global players are into it and therefore as a serious player, we want to be here in this space.

Q. Exports have been one your mainstays. Can you please comment on the export scenario at present?

A. The export business is not doing that great due to a number of factors. Last year, we had a revenue of Rs 1,000 crore but it has gone down in the current year. For example, Latin America is currently undergoing a currency turmoil, Middle Eastern countries are facing the wrath of falling fuel prices forcing them to cut on their spending. Both these markets form about 25-30% of our exports. However, there are some regions which are showing some signs of hope. We are now focusing on the South East Asian countries and going back to the US and European markets.

Q. How is the Mexico plant doing and what are the plans ahead for it?

A. Though the market volatility remains due to external factors, the capacity of plants in Mexico is under expansion. The capacity is expected to go up to 5 million tyres from the existing 3.5 million units per year.

Q. How will GST impact your business and the economy in general?

A. GST, it seems will make the logistic movement a lot smoother as a result of which the final cost of the product may come down, though it may vary from sector to sector. However, its implementation part is expected to be a pain, at least for some time to come before things settle down and we can see its benefit. We are waiting to see how it will impact the business we are in.

Q. You claim to have plans to create products out of waste. Can you elaborate on it?

A. Waste generated out of the industry can be put to better use which will help in creating a value out of it. A lot of such products can be created. For one such programme, we are in touch with Shoe Institute of India for creating shoes out of the waste. Plus it will also offer additional revenue and employment opportunities.

(The correspondent had recently visited JK Tyre's Vikrant plant on company's invitation)

![submenu-img]() BMW i5 M60 xDrive launched in India, all-electric sedan priced at Rs 11950000

BMW i5 M60 xDrive launched in India, all-electric sedan priced at Rs 11950000![submenu-img]() This superstar was arrested several times by age 17, thrown out of home, once had just Rs 250, now worth Rs 6600 crore

This superstar was arrested several times by age 17, thrown out of home, once had just Rs 250, now worth Rs 6600 crore![submenu-img]() Meet Reliance’s highest paid employee, gets over Rs 240000000 salary, he is Mukesh Ambani’s…

Meet Reliance’s highest paid employee, gets over Rs 240000000 salary, he is Mukesh Ambani’s… ![submenu-img]() Meet lesser-known relative of Mukesh Ambani, Anil Ambani, has worked with BCCI, he is married to...

Meet lesser-known relative of Mukesh Ambani, Anil Ambani, has worked with BCCI, he is married to...![submenu-img]() Made in just Rs 95,000, this film was a superhit, but destroyed lead actress' career, saw controversy over bold scenes

Made in just Rs 95,000, this film was a superhit, but destroyed lead actress' career, saw controversy over bold scenes![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here

DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here![submenu-img]() DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar

DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar![submenu-img]() DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth

DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth![submenu-img]() In pics: Arti Singh stuns in red lehenga as she ties the knot with beau Dipak Chauhan in dreamy wedding

In pics: Arti Singh stuns in red lehenga as she ties the knot with beau Dipak Chauhan in dreamy wedding![submenu-img]() Actors who died due to cosmetic surgeries

Actors who died due to cosmetic surgeries![submenu-img]() See inside pics: Malayalam star Aparna Das' dreamy wedding with Manjummel Boys actor Deepak Parambol

See inside pics: Malayalam star Aparna Das' dreamy wedding with Manjummel Boys actor Deepak Parambol ![submenu-img]() In pics: Salman Khan, Alia Bhatt, Rekha, Neetu Kapoor attend grand premiere of Sanjay Leela Bhansali's Heeramandi

In pics: Salman Khan, Alia Bhatt, Rekha, Neetu Kapoor attend grand premiere of Sanjay Leela Bhansali's Heeramandi![submenu-img]() Streaming This Week: Crakk, Tillu Square, Ranneeti, Dil Dosti Dilemma, latest OTT releases to binge-watch

Streaming This Week: Crakk, Tillu Square, Ranneeti, Dil Dosti Dilemma, latest OTT releases to binge-watch![submenu-img]() What is inheritance tax?

What is inheritance tax?![submenu-img]() DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?

DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?![submenu-img]() DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?

DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?![submenu-img]() DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence

DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence![submenu-img]() DNA Explainer: What is India's stand amid Iran-Israel conflict?

DNA Explainer: What is India's stand amid Iran-Israel conflict?![submenu-img]() This superstar was arrested several times by age 17, thrown out of home, once had just Rs 250, now worth Rs 6600 crore

This superstar was arrested several times by age 17, thrown out of home, once had just Rs 250, now worth Rs 6600 crore![submenu-img]() Made in just Rs 95,000, this film was a superhit, but destroyed lead actress' career, saw controversy over bold scenes

Made in just Rs 95,000, this film was a superhit, but destroyed lead actress' career, saw controversy over bold scenes![submenu-img]() Meet 72-year-old who earns Rs 280 cr per film, Asia's highest-paid actor, bigger than Shah Rukh, Salman, Akshay, Prabhas

Meet 72-year-old who earns Rs 280 cr per film, Asia's highest-paid actor, bigger than Shah Rukh, Salman, Akshay, Prabhas![submenu-img]() This star, who once lived in chawl, worked as tailor, later gave four Rs 200-crore films; he's now worth...

This star, who once lived in chawl, worked as tailor, later gave four Rs 200-crore films; he's now worth...![submenu-img]() Tamil star Prasanna reveals why he chose series Ranneeti for Hindi debut: 'Getting into Bollywood is not...'

Tamil star Prasanna reveals why he chose series Ranneeti for Hindi debut: 'Getting into Bollywood is not...'![submenu-img]() IPL 2024: Virat Kohli, Rajat Patidar fifties and disciplined bowling help RCB beat Sunrisers Hyderabad by 35 runs

IPL 2024: Virat Kohli, Rajat Patidar fifties and disciplined bowling help RCB beat Sunrisers Hyderabad by 35 runs![submenu-img]() 'This is the problem in India...': Wasim Akram's blunt take on fans booing Mumbai Indians skipper Hardik Pandya

'This is the problem in India...': Wasim Akram's blunt take on fans booing Mumbai Indians skipper Hardik Pandya![submenu-img]() KKR vs PBKS, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report

KKR vs PBKS, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report![submenu-img]() KKR vs PBKS IPL 2024 Dream11 prediction: Fantasy cricket tips for Kolkata Knight Riders vs Punjab Kings

KKR vs PBKS IPL 2024 Dream11 prediction: Fantasy cricket tips for Kolkata Knight Riders vs Punjab Kings![submenu-img]() IPL 2024: KKR star Rinku Singh finally gets another bat from Virat Kohli after breaking previous one - Watch

IPL 2024: KKR star Rinku Singh finally gets another bat from Virat Kohli after breaking previous one - Watch![submenu-img]() Viral video: Teacher's cute way to capture happy student faces melts internet, watch

Viral video: Teacher's cute way to capture happy student faces melts internet, watch![submenu-img]() Woman attends online meeting on scooter while stuck in traffic, video goes viral

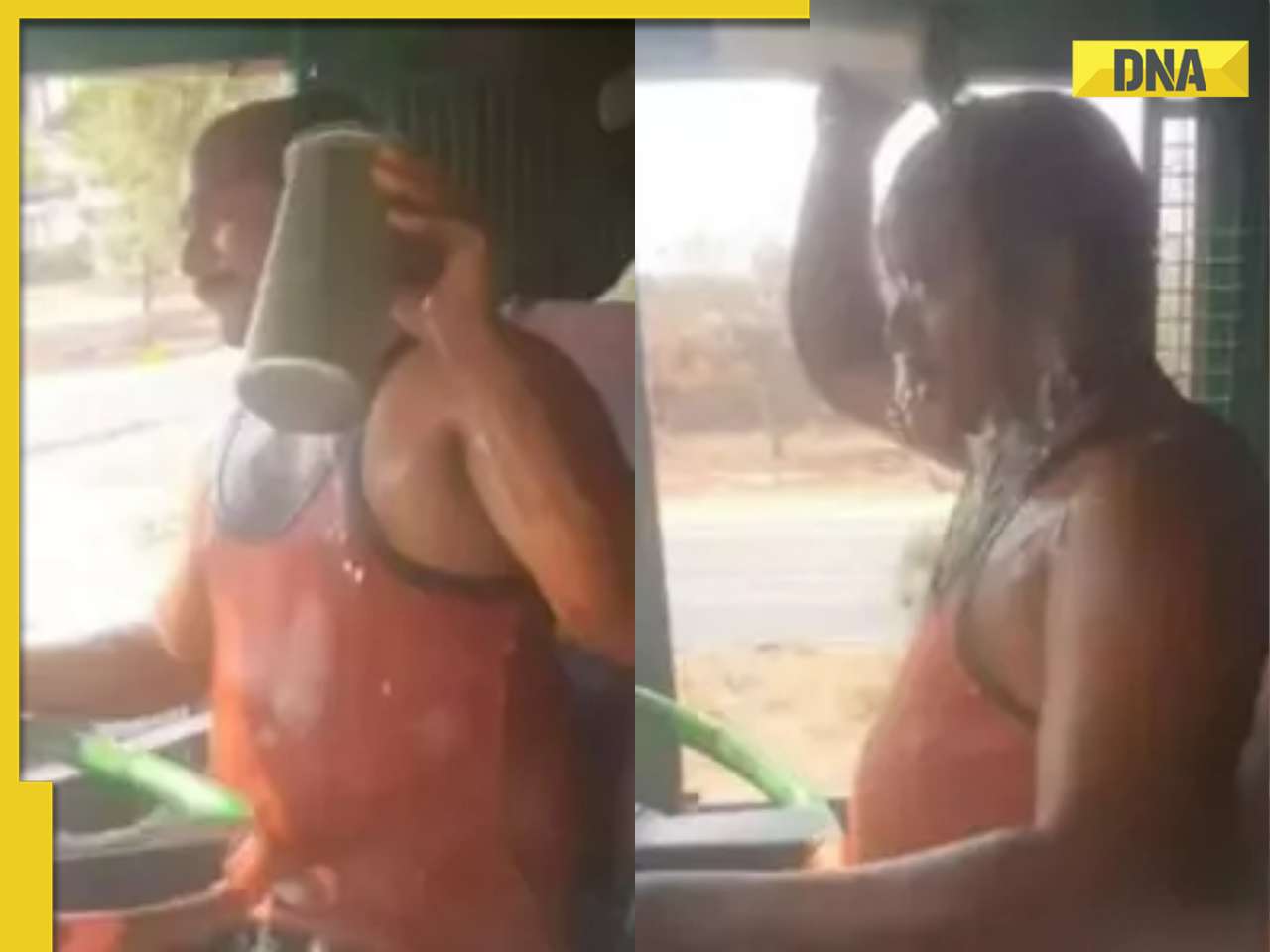

Woman attends online meeting on scooter while stuck in traffic, video goes viral![submenu-img]() Viral video: Pilot proposes to flight attendant girlfriend before takeoff, internet hearts it

Viral video: Pilot proposes to flight attendant girlfriend before takeoff, internet hearts it![submenu-img]() Pakistani teen receives life-saving heart transplant from Indian donor, details here

Pakistani teen receives life-saving heart transplant from Indian donor, details here![submenu-img]() Viral video: Truck driver's innovative solution to beat the heat impresses internet, watch

Viral video: Truck driver's innovative solution to beat the heat impresses internet, watch

)

)

)

)

)

)

)