With the curtains down on Singur, Tata and its ancillary suppliers will now have to pull out all stops to ensure smooth production and delivery schedules for Nano.

With the curtains down on Singur, Tata and its ancillary suppliers will now have to pull out all stops to ensure smooth production and delivery schedules for Nano.

There has been a huge setback already. The company had initially planned to produce nearly one-lakh cars this financial year which was later halved. Now, it looks as if barely 15,000 Nanos will roll out till end-March 2009.

The first step, of course, is for Tata Motors to choose its new plant. It already has three concrete offers from Gujarat, Karnataka and Maharashtra and top sources have confirmed to DNA that Gujarat is right on top of the list. It has the best in terms of ports, roads, power, water and, most importantly, zero labour trouble.

The site is reportedly less than 100 kilometres from Bhuj which means proximity to Mundra and Kandla Ports. The other important automobile resident of the state is General Motors with its plant in Halol near Vadodara.

The interesting part of the Nano business plan is a mother plant which will produce the cars and supply kits to satellite units in strategic parts of the country for easy distribution.

Gujarat, as the mother plant, would meet the needs of the western region while Uttarakhand and Dharwad (which produce the Tata Ace pickup and Marco Polo buses respectively) as satellite plants would ideally service the north and south.

The critical link in the Nano plan involves the 55 ancillary suppliers whose 300-acre cluster in Singur was the bone of contention in the tug-of-war between Mamata Banerjee and the WB government.

These vendors have already lost an estimated Rs500 crore but hope to get this compensated by the Tatas. Given the current slowdown, none of them would be ready to make any fresh investment in Gujarat and would much rather supply parts from their existing plants.

“Paying more for transport costs is better than setting up a new unit. We would rather have large warehouses for stocking parts which can be delivered to the plant on a just-in-time basis,” a top supplier for the Nano said. For the moment, however, Tata Motors has sought delivery of parts to its Uttarakhand plant while engine components will be diverted to the Pune facility. Eventually, completely assembled Nanos will emerge from Uttarakhand towards end-November though numbers will be really modest at 3,000 units a month.

![submenu-img]() ‘Paisa hi Paisa Hoga Ab’: Mukesh Ambani’s son Anant Ambani invites Pakistanis to UK estate, poses with ‘Bewafa’ singer…

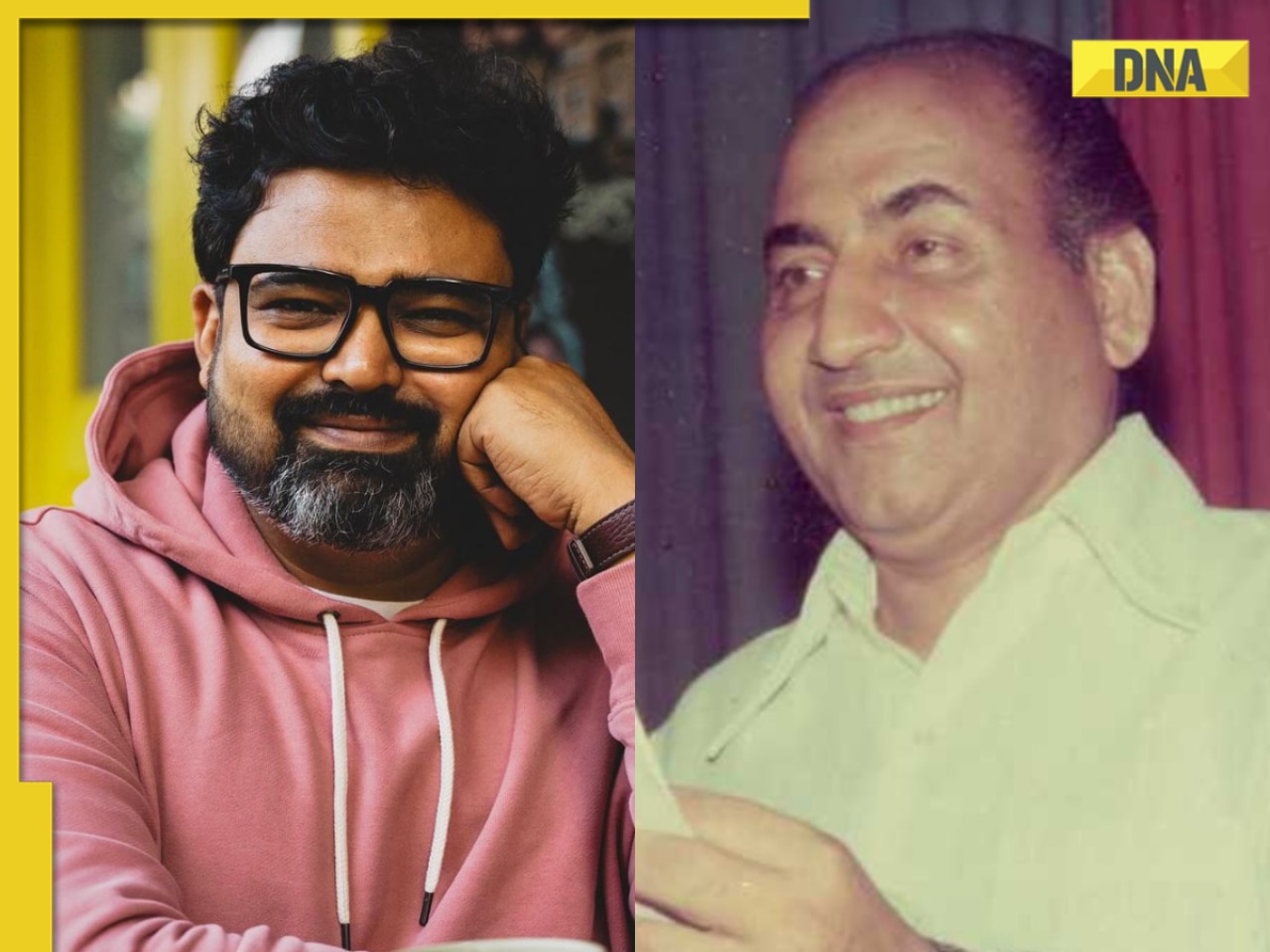

‘Paisa hi Paisa Hoga Ab’: Mukesh Ambani’s son Anant Ambani invites Pakistanis to UK estate, poses with ‘Bewafa’ singer…![submenu-img]() Raj Shekhar reacts to AI-generated Mohammed Rafi version of 'Pehle Bhi Main': 'I sent it to my father' | Exclusive

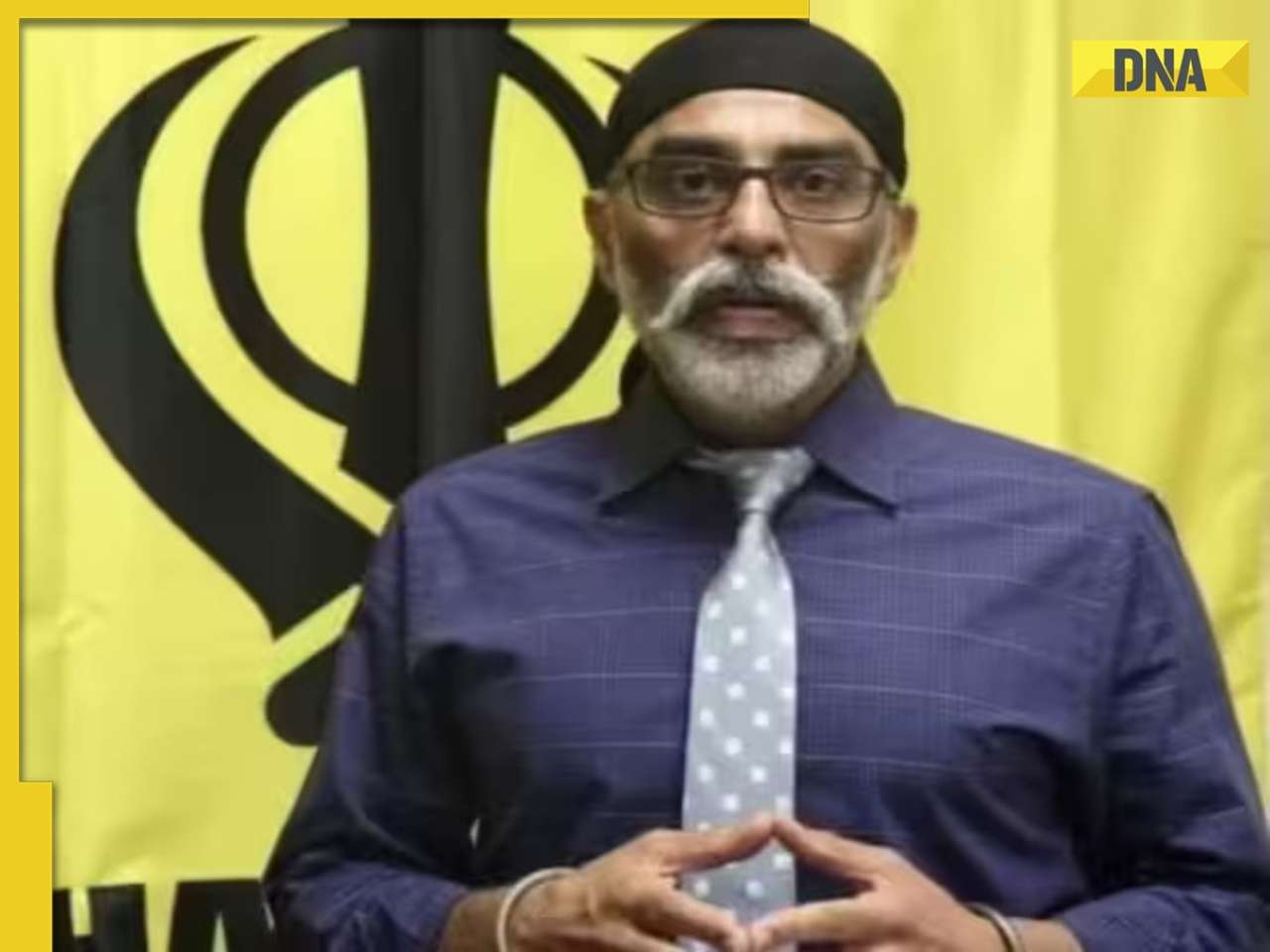

Raj Shekhar reacts to AI-generated Mohammed Rafi version of 'Pehle Bhi Main': 'I sent it to my father' | Exclusive ![submenu-img]() 'Unwarranted, unsubstantiated claims': India slams US media report on alleged Pannun murder plot

'Unwarranted, unsubstantiated claims': India slams US media report on alleged Pannun murder plot![submenu-img]() JD(s) to suspend NDA Hassan candidate Prajwal Revanna: Kumaraswamy

JD(s) to suspend NDA Hassan candidate Prajwal Revanna: Kumaraswamy![submenu-img]() AstraZeneca admits its COVID-19 vaccine Covishield can cause rare...

AstraZeneca admits its COVID-19 vaccine Covishield can cause rare...![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here

DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here![submenu-img]() DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar

DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar![submenu-img]() DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth

DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth![submenu-img]() Remember Heyy Babyy's cute 'Angel' Juanna Sanghvi? 20 year-old looks unrecognisable now, fans say 'her comeback will...'

Remember Heyy Babyy's cute 'Angel' Juanna Sanghvi? 20 year-old looks unrecognisable now, fans say 'her comeback will...'![submenu-img]() In pics: Arti Singh stuns in red lehenga as she ties the knot with beau Dipak Chauhan in dreamy wedding

In pics: Arti Singh stuns in red lehenga as she ties the knot with beau Dipak Chauhan in dreamy wedding![submenu-img]() Actors who died due to cosmetic surgeries

Actors who died due to cosmetic surgeries![submenu-img]() See inside pics: Malayalam star Aparna Das' dreamy wedding with Manjummel Boys actor Deepak Parambol

See inside pics: Malayalam star Aparna Das' dreamy wedding with Manjummel Boys actor Deepak Parambol ![submenu-img]() In pics: Salman Khan, Alia Bhatt, Rekha, Neetu Kapoor attend grand premiere of Sanjay Leela Bhansali's Heeramandi

In pics: Salman Khan, Alia Bhatt, Rekha, Neetu Kapoor attend grand premiere of Sanjay Leela Bhansali's Heeramandi![submenu-img]() DNA Explainer: Why Harvey Weinstein's rape conviction was overturned, will beleaguered Hollywood mogul get out of jail?

DNA Explainer: Why Harvey Weinstein's rape conviction was overturned, will beleaguered Hollywood mogul get out of jail?![submenu-img]() What is inheritance tax?

What is inheritance tax?![submenu-img]() DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?

DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?![submenu-img]() DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?

DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?![submenu-img]() DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence

DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence![submenu-img]() Raj Shekhar reacts to AI-generated Mohammed Rafi version of 'Pehle Bhi Main': 'I sent it to my father' | Exclusive

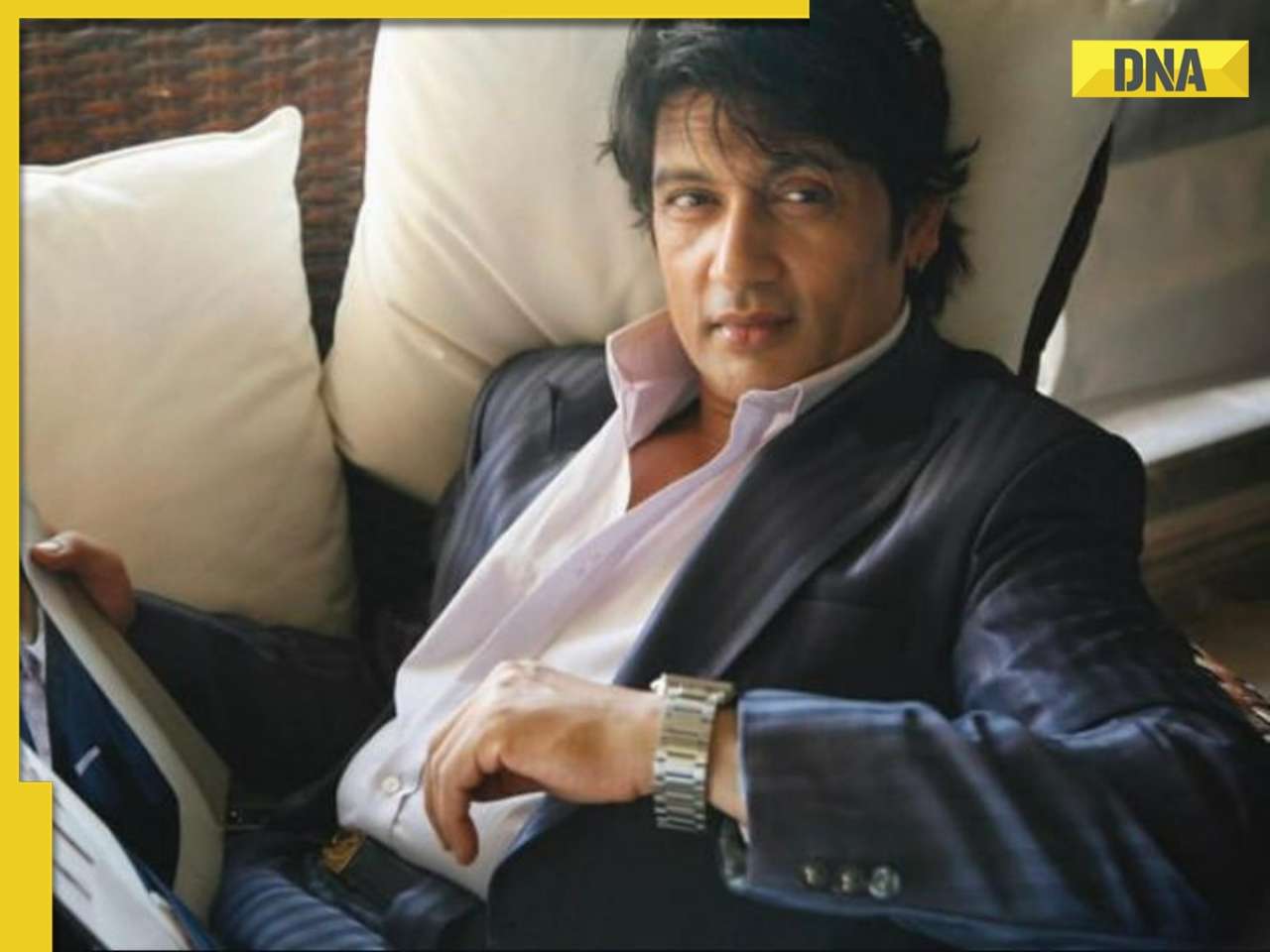

Raj Shekhar reacts to AI-generated Mohammed Rafi version of 'Pehle Bhi Main': 'I sent it to my father' | Exclusive ![submenu-img]() Shekhar Suman slams young actors who ‘want stardom overnight’: ‘Why do they act…’

Shekhar Suman slams young actors who ‘want stardom overnight’: ‘Why do they act…’![submenu-img]() Meet man who lived naked, alone, away from civilisation for 'cruel' reality show; remained in trauma for years, is now..

Meet man who lived naked, alone, away from civilisation for 'cruel' reality show; remained in trauma for years, is now..![submenu-img]() Meet actor, who failed auditions, was thrown out of theatre, a curfew made him superstar; he’s now worth Rs 1800 crore

Meet actor, who failed auditions, was thrown out of theatre, a curfew made him superstar; he’s now worth Rs 1800 crore![submenu-img]() Meet actor, who became star overnight, was called superhero of children, later quit acting; he now works as...

Meet actor, who became star overnight, was called superhero of children, later quit acting; he now works as...![submenu-img]() IPL 2024: Varun Chakaravarthy, Phil Salt power Kolkata Knight Riders to 7-wicket win over Delhi Capitals

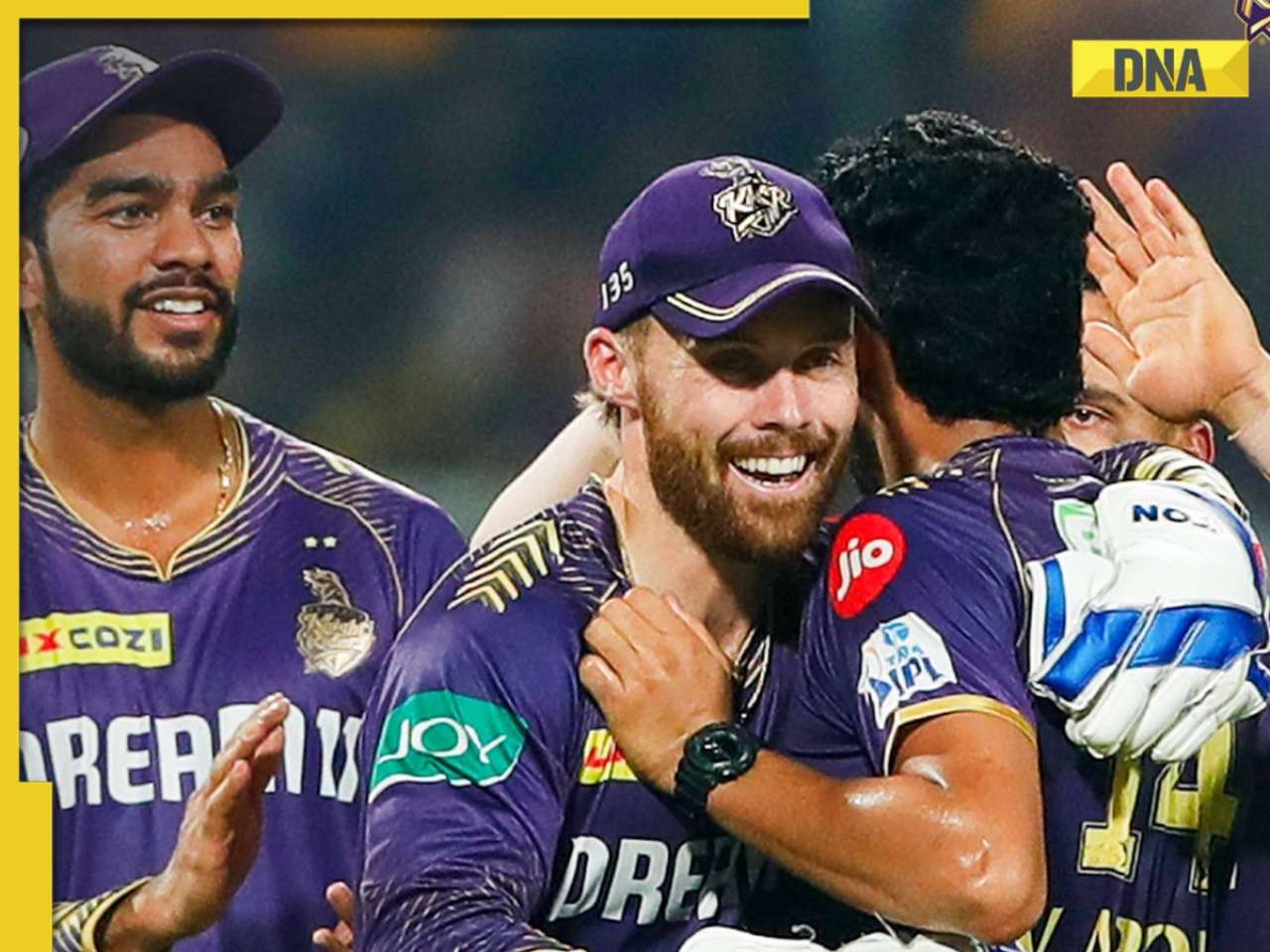

IPL 2024: Varun Chakaravarthy, Phil Salt power Kolkata Knight Riders to 7-wicket win over Delhi Capitals![submenu-img]() 'Won't find a place in my team': Virender Sehwag slams legendary India player for his comments on T20 cricket

'Won't find a place in my team': Virender Sehwag slams legendary India player for his comments on T20 cricket![submenu-img]() 'When people create imbalances....': Virat Kohli's sister reacts to RCB batter's strike rate chatter in IPL 2024

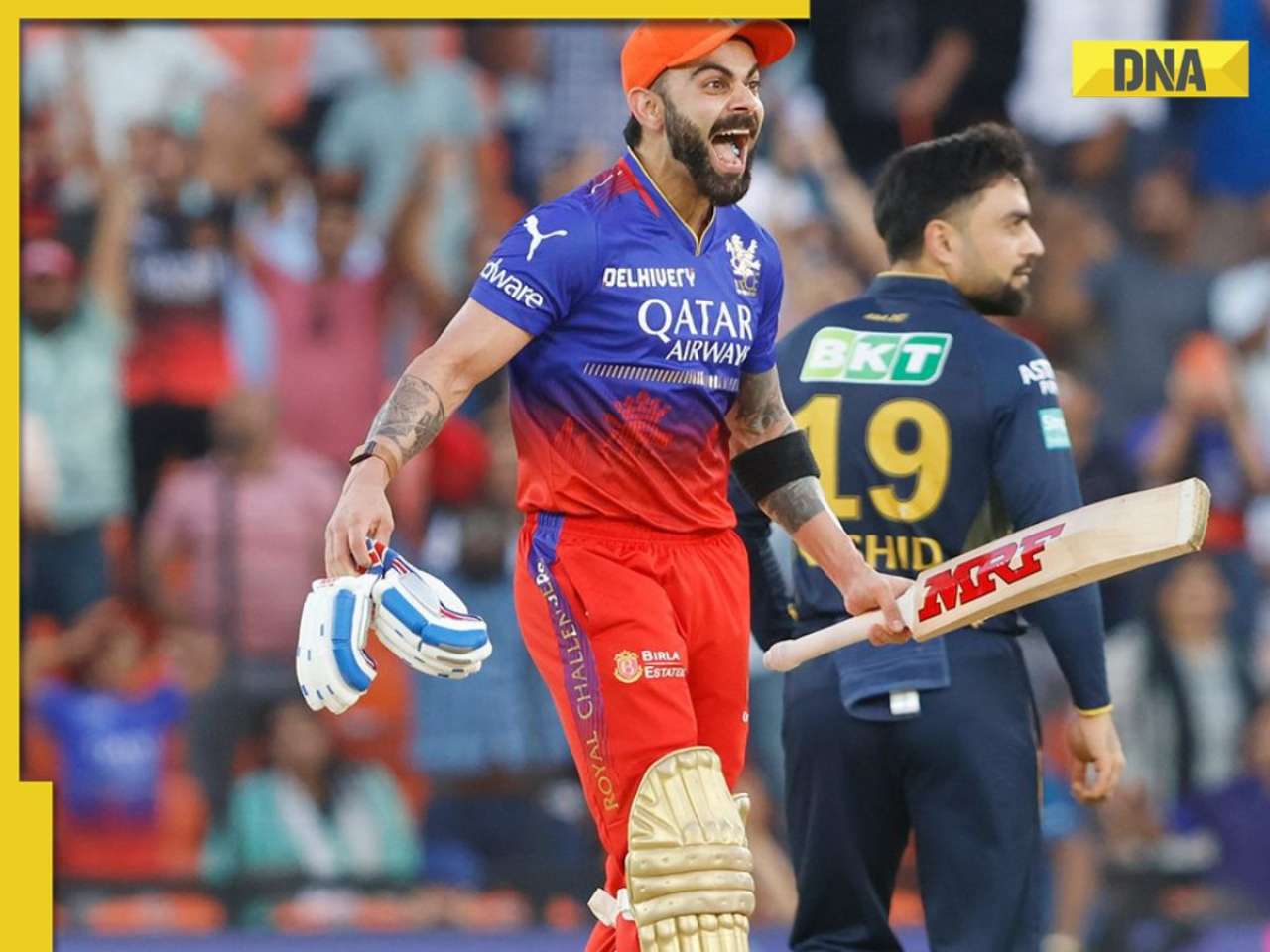

'When people create imbalances....': Virat Kohli's sister reacts to RCB batter's strike rate chatter in IPL 2024![submenu-img]() LSG vs MI, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report

LSG vs MI, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report![submenu-img]() LSG vs MI IPL 2024 Dream11 prediction: Fantasy cricket tips for Lucknow Super Giants vs Mumbai Indians

LSG vs MI IPL 2024 Dream11 prediction: Fantasy cricket tips for Lucknow Super Giants vs Mumbai Indians![submenu-img]() Viral Video: 4 girls get into ugly fight on Noida road, fly punches, pull hair; watch

Viral Video: 4 girls get into ugly fight on Noida road, fly punches, pull hair; watch![submenu-img]() Private jets, pyramids and more: Indian-origin billionaire Ankur Jain marries ex-WWE star Erika Hammond in Egypt

Private jets, pyramids and more: Indian-origin billionaire Ankur Jain marries ex-WWE star Erika Hammond in Egypt![submenu-img]() Viral video captures mama tiger and cubs' playful time in Ranthambore, watch

Viral video captures mama tiger and cubs' playful time in Ranthambore, watch![submenu-img]() Heartwarming video of cat napping among puppies goes viral, watch

Heartwarming video of cat napping among puppies goes viral, watch![submenu-img]() Viral video: Man squeezes his body through tennis racquet, internet is stunned

Viral video: Man squeezes his body through tennis racquet, internet is stunned

)

)

)

)

)

)