Graviky, the company, however, says that their primary goal is to reduce air pollution through their trademarked product titled Kaalink

A Bengaluru-based firm has found a way to trap pollutants, separate the carbon from the particulate matter and use this carbon to make ink. This novel process shows us ways in recycling air pollution and could pave the way to tackle pollution-related issues that plague several parts of India.

Graviky Labs, the company behind the innovation, is a MIT Media Lab Spin-off. The company was founded by MIT Media Lab alumnus Anirudh Sharma with Nikhil Kaushik and Nitesh Kadyan. The company, in their website, say that they fuse disciplines, technologies, design thinking to build high impact deployable systems, products and visions. “Our current area of work is applying high technology and design thinking to environment issues,” they say.

Video Source: Tiger Beer and Graviky

Although the trio are based out of Bengaluru, all of them grew up in Delhi. “We know how bad Delhi gets. There’s smog in winter and the temperatures are higher in summer, primarily because of the pollutants. That’s when Anirudh had a ‘eureka’ moment,” said Nikhil, while speaking to dna over telephone.

The theory is simple: carbonaceous emissions from engines are black in colour. Anirudh came up with the potential of capturing pollution and repurposing it to use as ink. “We thought what if we could use it as a pigment for colouring. We then tied up with several designers, artists, chemists, and automobile experts to make this a reality,” added Nikhil.

The ink is created through a three-step process. In the first stage, Graviky’s trademarked product Kaalink, a contraption retrofitted to the exhaust pipes of vehicles, captures soot emitted from the automobiles. When we questioned whether it would affect the engine, given that Kaalink was attached on the exhaust pipe, Nikhil said that the contraption has been designed in such a way so that the hot air escapes the vehicle and the particulate matter is left behind.

In the second step, the collected soot undergoes various proprietary processes to remove heavy metals and carcinogens. The end product is purified carbon pigment – a core ingredient used in making ink and paints. “We process the captured pollution to remove the heavy metals and carcinogens. However, the inks used for art work/graffiti etc are not fit for inhalation/ingestion. This is similar for any other ink or paint. The artists are aware of the risks and take standard precautions for their safety,” he said.

The entire process has been tested out in Hong Kong, where the Graviky team in association with Tiger Beer used 2,500 hours worth of carbon emissions to create 150 litres of Air-ink, using which the artists painted the streets of Hong Kong. It was a stunning amalgamation of science and art to create something beautiful out of thin air.

Although they are doing their bit to curb air pollution, albeit on a small scale (which hopefully could become a large-scale project in future), the team at Graviky know that they have their work cut out for them. “Firstly, pollution isn’t going away anytime soon. Secondly, thermal power is still a leading source of energy, despite the availability of renewable alternatives,” says Nikhil.

The team adds that it will be a while before clean energy replaces polluting fuels. While Graviky has made this ink using soot, it wants go a step further to repurpose the soot to make carbon nano-tubes.

Although Kaalink isn’t commercially available as yet, Nikhil tells us that the plan is to not start selling it to individual customers. “We would ideally look at public vehicles like buses and taxis that dock at a particular point every day. This area will have specially trained individuals to remove the particulate matter and separate it from soot,” he said, adding that the final goal is to take the company’s inks anywhere and do their bit to reduce air pollution. “We are working improving the efficiency of capturing processes. A separate effort is being made to broaden our portfolio by adding more varieties of inks and paints,” said Nikhil

![submenu-img]() Explainer: Why Spain's PM Pedro Sanchez is taking break from public duties?

Explainer: Why Spain's PM Pedro Sanchez is taking break from public duties?![submenu-img]() Meet superstar who was made to kiss 10 men during audition, feared being called 'difficult', net worth is..

Meet superstar who was made to kiss 10 men during audition, feared being called 'difficult', net worth is..![submenu-img]() Mukesh Ambani's Reliance makes big announcement, unveils new free…

Mukesh Ambani's Reliance makes big announcement, unveils new free…![submenu-img]() Secret Service agent protecting US Vice President Kamala Harris removed after brawl with other officers

Secret Service agent protecting US Vice President Kamala Harris removed after brawl with other officers![submenu-img]() Who is Iranian rapper Toomaj Salehi, why is he sentenced to death? Know on what charges

Who is Iranian rapper Toomaj Salehi, why is he sentenced to death? Know on what charges![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here

DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here![submenu-img]() DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar

DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar![submenu-img]() DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth

DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth![submenu-img]() In pics: Salman Khan, Alia Bhatt, Rekha, Neetu Kapoor attend grand premiere of Sanjay Leela Bhansali's Heeramandi

In pics: Salman Khan, Alia Bhatt, Rekha, Neetu Kapoor attend grand premiere of Sanjay Leela Bhansali's Heeramandi![submenu-img]() Streaming This Week: Crakk, Tillu Square, Ranneeti, Dil Dosti Dilemma, latest OTT releases to binge-watch

Streaming This Week: Crakk, Tillu Square, Ranneeti, Dil Dosti Dilemma, latest OTT releases to binge-watch![submenu-img]() From Salman Khan to Shah Rukh Khan: Actors who de-aged for films before Amitabh Bachchan in Kalki 2898 AD

From Salman Khan to Shah Rukh Khan: Actors who de-aged for films before Amitabh Bachchan in Kalki 2898 AD![submenu-img]() Remember Abhishek Sharma? Hrithik Roshan's brother from Kaho Naa Pyaar Hai has become TV star, is married to..

Remember Abhishek Sharma? Hrithik Roshan's brother from Kaho Naa Pyaar Hai has become TV star, is married to..![submenu-img]() Remember Ali Haji? Aamir Khan, Kajol's son in Fanaa, who is now director, writer; here's how charming he looks now

Remember Ali Haji? Aamir Khan, Kajol's son in Fanaa, who is now director, writer; here's how charming he looks now![submenu-img]() What is inheritance tax?

What is inheritance tax?![submenu-img]() DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?

DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?![submenu-img]() DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?

DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?![submenu-img]() DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence

DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence![submenu-img]() DNA Explainer: What is India's stand amid Iran-Israel conflict?

DNA Explainer: What is India's stand amid Iran-Israel conflict?![submenu-img]() Meet superstar who was made to kiss 10 men during audition, feared being called 'difficult', net worth is..

Meet superstar who was made to kiss 10 men during audition, feared being called 'difficult', net worth is..![submenu-img]() Lara Dutta has this to say about trolls calling her ‘buddhi, moti’: ‘I don’t know what someone like that…’

Lara Dutta has this to say about trolls calling her ‘buddhi, moti’: ‘I don’t know what someone like that…’![submenu-img]() Meet actress, who gave first Rs 100-crore Tamil film; and it’s not Anushka Shetty, Nayanthara, Jyotika, or Trisha

Meet actress, who gave first Rs 100-crore Tamil film; and it’s not Anushka Shetty, Nayanthara, Jyotika, or Trisha ![submenu-img]() Meet actor, school dropout, who worked as mechanic, salesman, later became star; now earns over Rs 100 crore per film

Meet actor, school dropout, who worked as mechanic, salesman, later became star; now earns over Rs 100 crore per film![submenu-img]() This filmmaker earned Rs 150 as junior artiste, bunked college for work, now heads production house worth crores

This filmmaker earned Rs 150 as junior artiste, bunked college for work, now heads production house worth crores![submenu-img]() IPL 2024: Rishabh Pant, Axar Patel shine as Delhi Capitals beat Gujarat Titans by 4 runs

IPL 2024: Rishabh Pant, Axar Patel shine as Delhi Capitals beat Gujarat Titans by 4 runs![submenu-img]() SRH vs RCB, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report

SRH vs RCB, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report![submenu-img]() SRH vs RCB IPL 2024 Dream11 prediction: Fantasy cricket tips for Sunrisers Hyderabad vs Royal Challengers Bengaluru

SRH vs RCB IPL 2024 Dream11 prediction: Fantasy cricket tips for Sunrisers Hyderabad vs Royal Challengers Bengaluru ![submenu-img]() Meet India cricketer who wanted to be IPS officer, got entry in IPL by luck, now earns more than CSK star Dhoni, he is..

Meet India cricketer who wanted to be IPS officer, got entry in IPL by luck, now earns more than CSK star Dhoni, he is..![submenu-img]() IPL 2024: Marcus Stoinis' century power LSG to 6-wicket win over CSK

IPL 2024: Marcus Stoinis' century power LSG to 6-wicket win over CSK![submenu-img]() Viral video: Truck driver's innovative solution to beat the heat impresses internet, watch

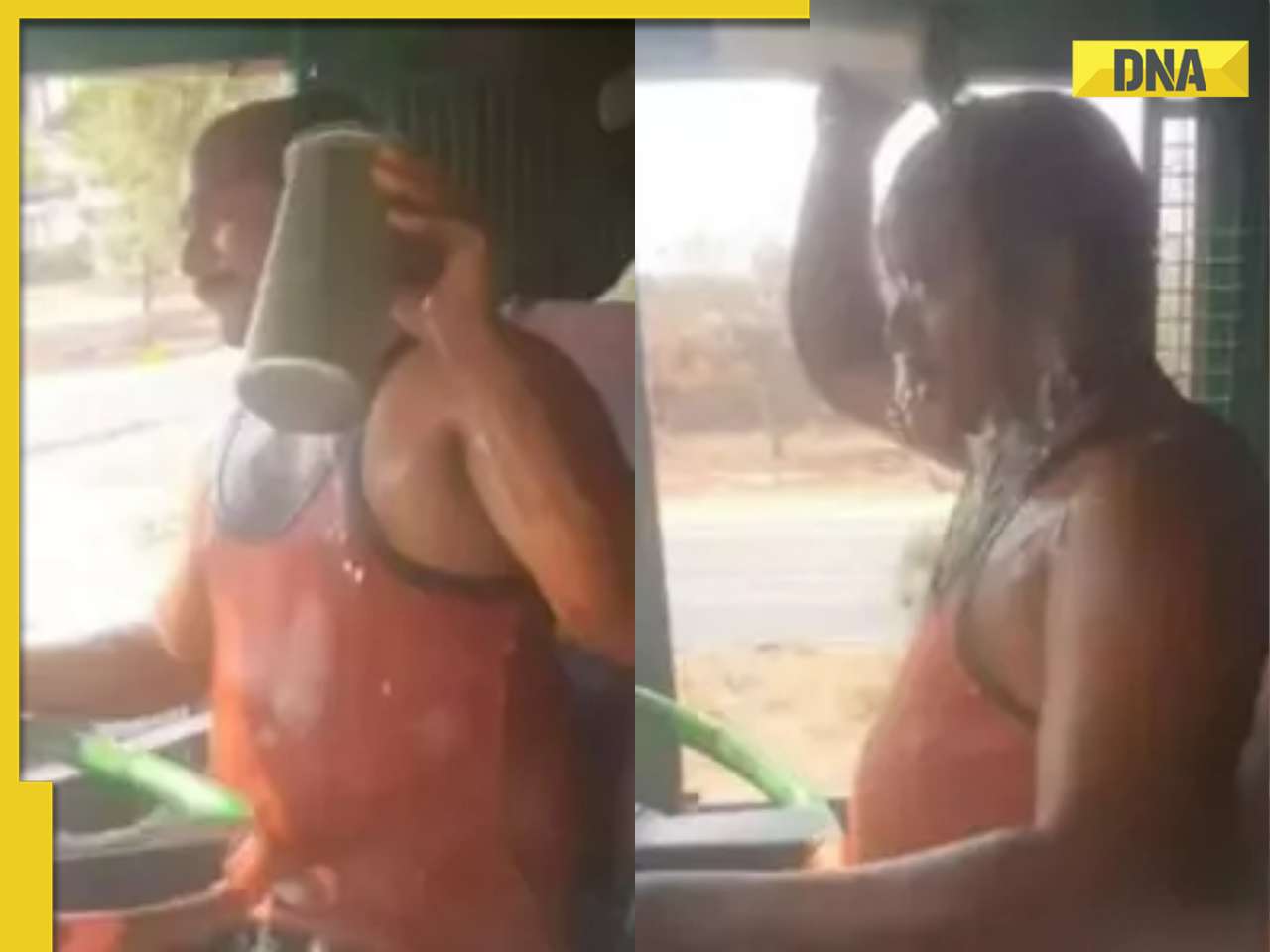

Viral video: Truck driver's innovative solution to beat the heat impresses internet, watch![submenu-img]() 'Look between E and Y on your keyboard': All you need to know about new 'X' trend

'Look between E and Y on your keyboard': All you need to know about new 'X' trend![submenu-img]() Watch: Pet dog scares off alligator in viral video, internet reacts

Watch: Pet dog scares off alligator in viral video, internet reacts![submenu-img]() Professional Indian gamers earn unbelievable amounts of money amid gaming boom; Know about their annual earnings

Professional Indian gamers earn unbelievable amounts of money amid gaming boom; Know about their annual earnings![submenu-img]() Meet first Asian woman without arms to get driving licence, she is from...

Meet first Asian woman without arms to get driving licence, she is from...

)

)

)

)

)

)

)