Scientists have built a new robotic gripper with soft fingers that can pick up and manipulate a range of objects and perform tasks such as screwing in a light bulb. The team from University of California (UC) San Diego in the US built the gripper that can pick up and manipulate objects without seeing them and needing to be trained. The gripper is unique because it brings together three different capabilities. It can twist objects; it can sense objects; and it can build models of the objects it is manipulating.

Scientists have built a new robotic gripper with soft fingers that can pick up and manipulate a range of objects and perform tasks such as screwing in a light bulb. The team from University of California (UC) San Diego in the US built the gripper that can pick up and manipulate objects without seeing them and needing to be trained. The gripper is unique because it brings together three different capabilities. It can twist objects; it can sense objects; and it can build models of the objects it is manipulating.

This allows the gripper to operate in low light and low visibility conditions, researchers said. They tested the gripper on an industrial robot and demonstrated that it could pick up, manipulate and model a wide range of objects, from lightbulbs to screwdrivers. "We designed the device to mimic what happens when you reach into your pocket and feel for your keys," said Michael T Tolley, a roboticist at UC San Diego.

The gripper has three fingers. Each finger is made of three soft flexible pneumatic chambers, which move when air pressure is applied. This gives the gripper more than one degree of freedom, so it can actually manipulate the objects it is holding. For example, the gripper can turn screwdrivers, screw in lightbulbs and even hold pieces of paper, thanks to this design.

In addition, each finger is covered with a smart, sensing skin. The skin is made of silicone rubber, where sensors made of conducting carbon nanotubes are embedded. The sheets of rubber are then rolled up, sealed and slipped onto the flexible fingers to cover them like skin. The conductivity of the nanotubes changes as the fingers flex, which allows the sensing skin to record and detect when the fingers are moving and coming into contact with an object. The data the sensors generate is transmitted to a control board, which puts the information together to create a 3D model of the object the gripper is manipulating.

It is a process similar to a CT scan, where 2D image slices add up to a 3D picture. The breakthroughs were possible because of the team's diverse expertise and their experience in the fields of soft robotics and manufacturing, Tolley said. Next steps include adding machine learning and artificial intelligence to data processing so that the gripper will actually be able to identify the objects it is manipulating, rather than just model them. Researchers also are investigating using 3D printing for the gripper's fingers to make them more durable.

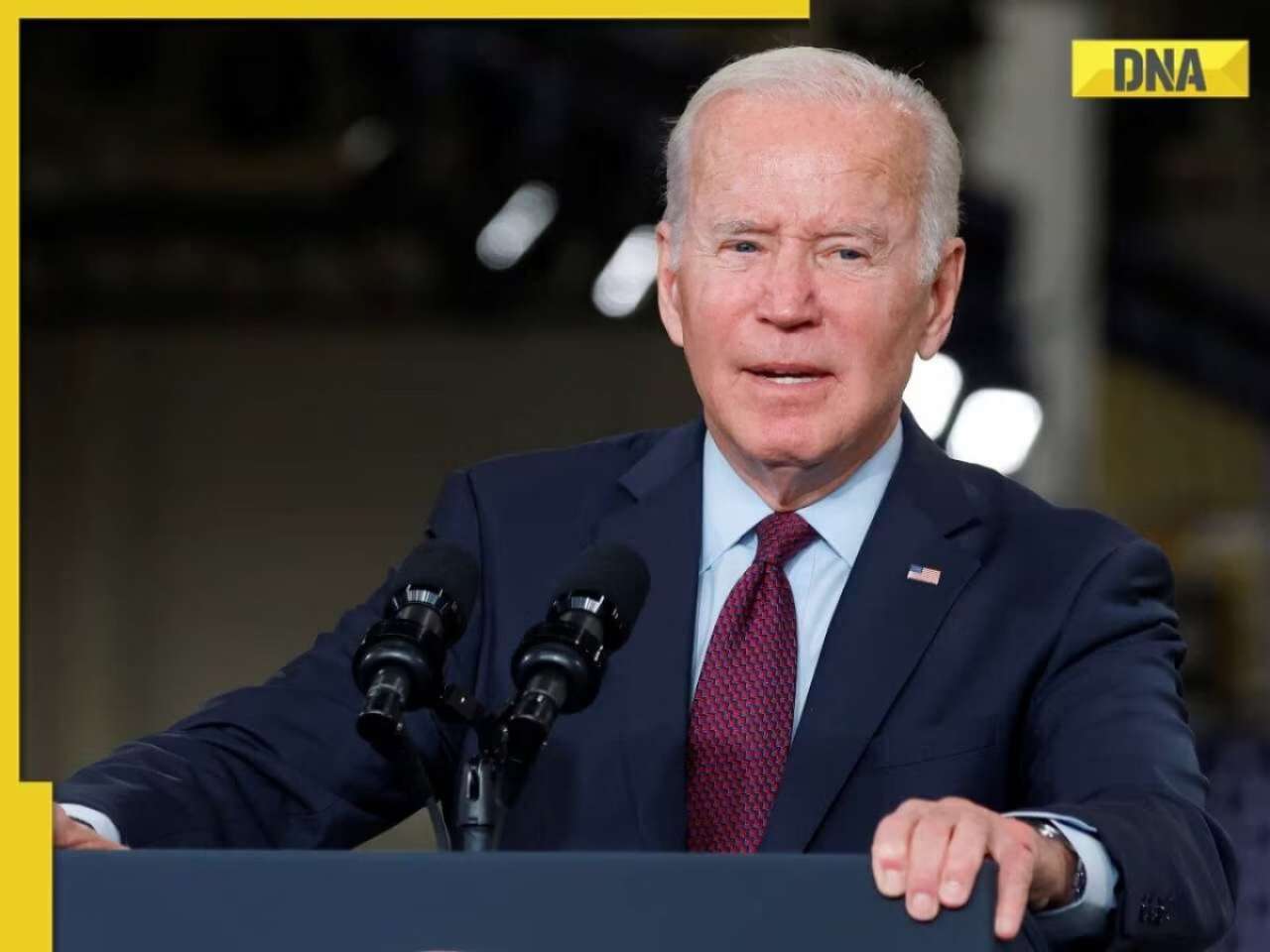

![submenu-img]() US imposes sanctions on Chinese, Belarus firms for providing ballistic missile tech to Pakistan

US imposes sanctions on Chinese, Belarus firms for providing ballistic missile tech to Pakistan![submenu-img]() 'Don't have any comment': White House mum on reports of Israeli strikes in Iran

'Don't have any comment': White House mum on reports of Israeli strikes in Iran![submenu-img]() Yes Bank co-founder Rana Kapoor gets bail after four years in bank fraud case

Yes Bank co-founder Rana Kapoor gets bail after four years in bank fraud case![submenu-img]() Barmer Lok Sabha Polls 2024: Check key candidates, date of voting and other important details

Barmer Lok Sabha Polls 2024: Check key candidates, date of voting and other important details![submenu-img]() This star once lived in garage, earned Rs 51 as first salary; now charges Rs 5 crore per film, is worth Rs 335 crore

This star once lived in garage, earned Rs 51 as first salary; now charges Rs 5 crore per film, is worth Rs 335 crore![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here

DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here![submenu-img]() DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar

DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar![submenu-img]() DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth

DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth![submenu-img]() Remember Ali Haji? Aamir Khan, Kajol's son in Fanaa, who is now director, writer; here's how charming he looks now

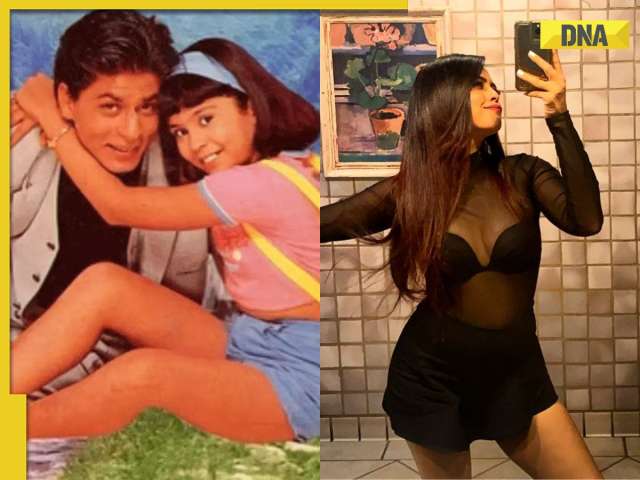

Remember Ali Haji? Aamir Khan, Kajol's son in Fanaa, who is now director, writer; here's how charming he looks now![submenu-img]() Remember Sana Saeed? SRK's daughter in Kuch Kuch Hota Hai, here's how she looks after 26 years, she's dating..

Remember Sana Saeed? SRK's daughter in Kuch Kuch Hota Hai, here's how she looks after 26 years, she's dating..![submenu-img]() In pics: Rajinikanth, Kamal Haasan, Mani Ratnam, Suriya attend S Shankar's daughter Aishwarya's star-studded wedding

In pics: Rajinikanth, Kamal Haasan, Mani Ratnam, Suriya attend S Shankar's daughter Aishwarya's star-studded wedding![submenu-img]() In pics: Sanya Malhotra attends opening of school for neurodivergent individuals to mark World Autism Month

In pics: Sanya Malhotra attends opening of school for neurodivergent individuals to mark World Autism Month![submenu-img]() Remember Jibraan Khan? Shah Rukh's son in Kabhi Khushi Kabhie Gham, who worked in Brahmastra; here’s how he looks now

Remember Jibraan Khan? Shah Rukh's son in Kabhi Khushi Kabhie Gham, who worked in Brahmastra; here’s how he looks now![submenu-img]() DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?

DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?![submenu-img]() DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?

DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?![submenu-img]() DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence

DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence![submenu-img]() DNA Explainer: What is India's stand amid Iran-Israel conflict?

DNA Explainer: What is India's stand amid Iran-Israel conflict?![submenu-img]() DNA Explainer: Why Iran attacked Israel with hundreds of drones, missiles

DNA Explainer: Why Iran attacked Israel with hundreds of drones, missiles![submenu-img]() This star once lived in garage, earned Rs 51 as first salary; now charges Rs 5 crore per film, is worth Rs 335 crore

This star once lived in garage, earned Rs 51 as first salary; now charges Rs 5 crore per film, is worth Rs 335 crore![submenu-img]() Meet actress, who worked as cook for free food, mopped floors, one Instagram post changed her life, is now worth…

Meet actress, who worked as cook for free food, mopped floors, one Instagram post changed her life, is now worth… ![submenu-img]() UP man arrested for booking cab from Salman Khan's house under Lawrence Bishnoi's name

UP man arrested for booking cab from Salman Khan's house under Lawrence Bishnoi's name ![submenu-img]() 'Justice milega': Ankita Lokhande talks about Sushant Singh Rajput, reveals she's still connected with his family

'Justice milega': Ankita Lokhande talks about Sushant Singh Rajput, reveals she's still connected with his family![submenu-img]() Rajkummar Rao reacts to plastic surgery rumours, admits he got fillers: 'If something gives me confidence...'

Rajkummar Rao reacts to plastic surgery rumours, admits he got fillers: 'If something gives me confidence...'![submenu-img]() IPL 2024: KL Rahul, Quinton de Kock star in Lucknow Super Giants' dominating 8-wicket win over Chennai Super Kings

IPL 2024: KL Rahul, Quinton de Kock star in Lucknow Super Giants' dominating 8-wicket win over Chennai Super Kings![submenu-img]() DC vs SRH, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report

DC vs SRH, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report![submenu-img]() Watch: Virat Kohli's cheeky 'your wife' remark to Dinesh Karthik leaves RCB teammates in splits

Watch: Virat Kohli's cheeky 'your wife' remark to Dinesh Karthik leaves RCB teammates in splits ![submenu-img]() DC vs SRH IPL 2024 Dream11 prediction: Fantasy cricket tips for Delhi Capitals vs Sunrisers Hyderabad

DC vs SRH IPL 2024 Dream11 prediction: Fantasy cricket tips for Delhi Capitals vs Sunrisers Hyderabad![submenu-img]() 'Kohli said it's not an option, just...': KL Rahul recalls his IPL debut for RCB in 2013

'Kohli said it's not an option, just...': KL Rahul recalls his IPL debut for RCB in 2013![submenu-img]() Canada's biggest heist: Two Indian-origin men among six arrested for Rs 1300 crore cash, gold theft

Canada's biggest heist: Two Indian-origin men among six arrested for Rs 1300 crore cash, gold theft![submenu-img]() Donuru Ananya Reddy, who secured AIR 3 in UPSC CSE 2023, calls Virat Kohli her inspiration, says…

Donuru Ananya Reddy, who secured AIR 3 in UPSC CSE 2023, calls Virat Kohli her inspiration, says…![submenu-img]() Nestle getting children addicted to sugar, Cerelac contains 3 grams of sugar per serving in India but not in…

Nestle getting children addicted to sugar, Cerelac contains 3 grams of sugar per serving in India but not in…![submenu-img]() Viral video: Woman enters crowded Delhi bus wearing bikini, makes obscene gesture at passenger, watch

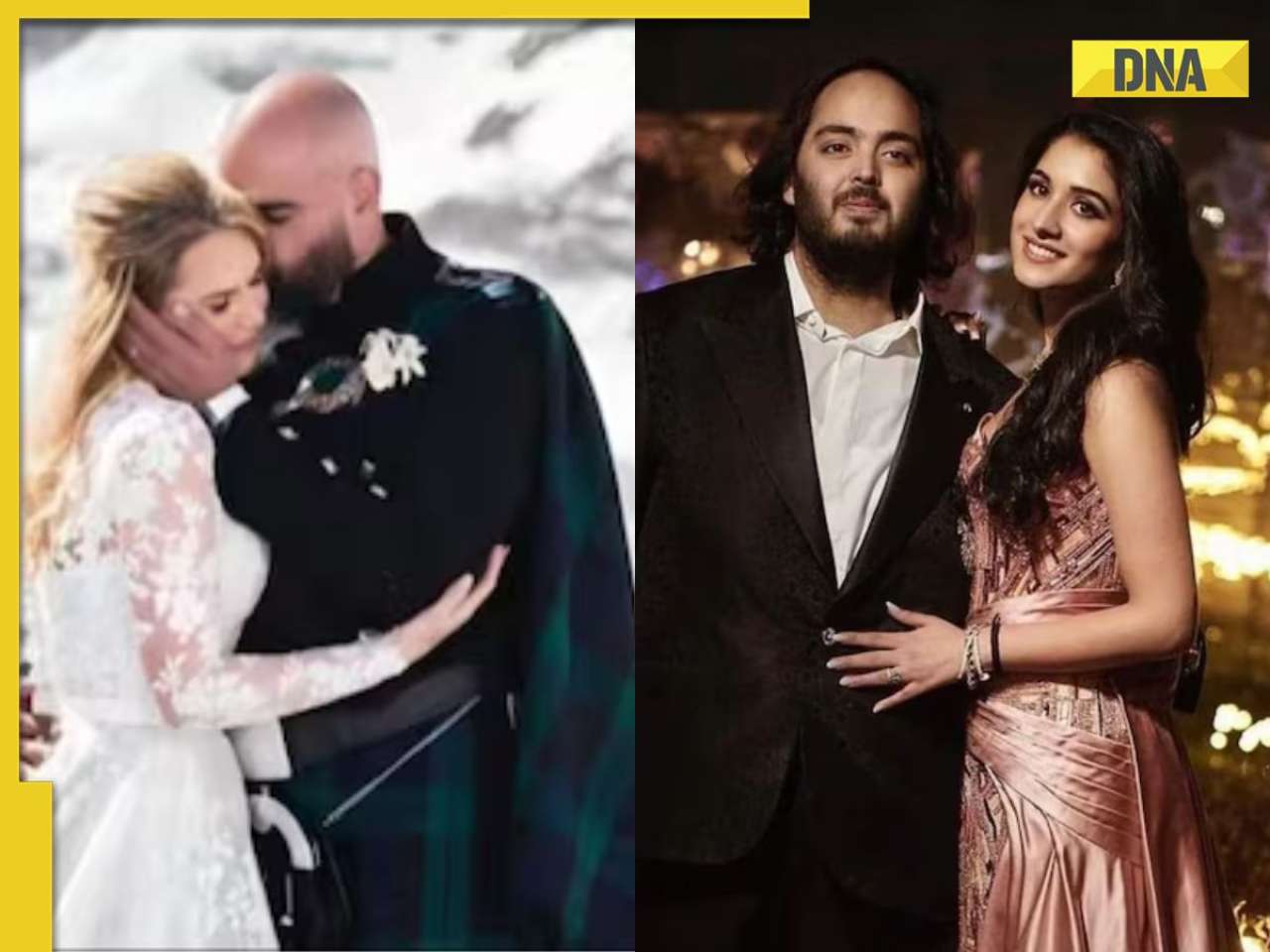

Viral video: Woman enters crowded Delhi bus wearing bikini, makes obscene gesture at passenger, watch![submenu-img]() This Swiss Alps wedding outshine Mukesh Ambani's son Anant Ambani's Jamnagar pre-wedding gala

This Swiss Alps wedding outshine Mukesh Ambani's son Anant Ambani's Jamnagar pre-wedding gala

)

)

)

)

)

)

)