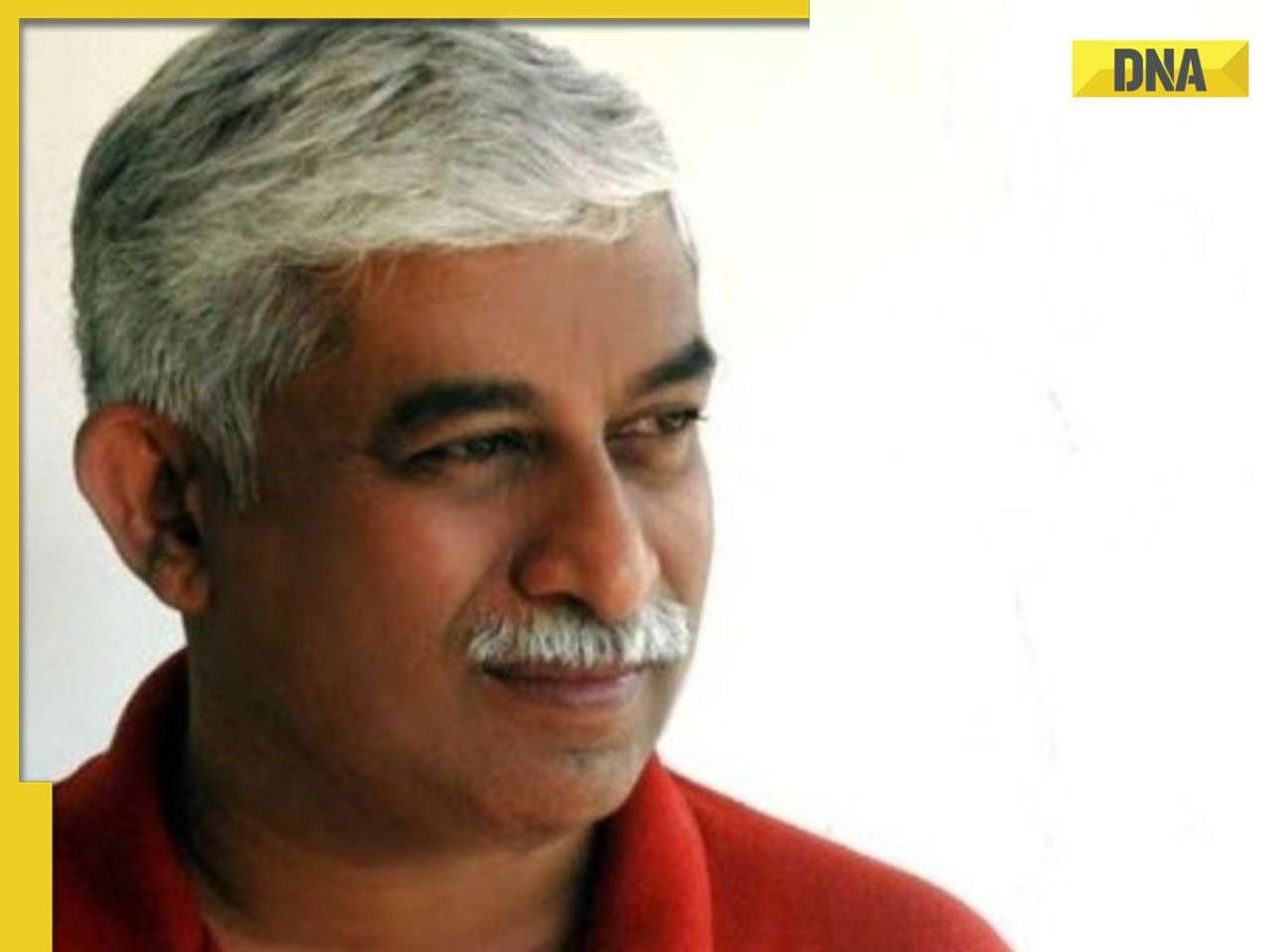

H R Jagannath, CEO of AIESL, in a freewheeling chat with Shahkar Abidi, spoke about all the facilities offered by Air India Engineering Services Ltd (AIESL).

Air India Engineering Services Ltd (AIESL) provides maintenance, repair, and overhaul (MRO) services for aircraft and was hived from the parent company Air India as part of turnaround plan. The construction work for its Nagpur MRO commenced in March 2011 and in December 2014, the facility was handed over to AIESL, which began its operations on August 27, 2015. The Air India subsidiary has now secured business from various Indian airlines including Jet Airways and SpiceJet. On AIESL's invitation, dna recently visited their MRO hub in Nagpur. AIESL also has MRO facilities in Delhi, Mumbai, Hyderabad, Thiruvananthapuram and Kolkata. HR Jagannath, CEO of AIESL, in a freewheeling chat with Shahkar Abidi, spoke about all the facilities offered by AIESL, how he plans to turn it into a self-sustained and profitable firm in next five years, among other things.

Q. You signed a Memorandum of Understanding (MoU) with low-cost carrier SpiceJet for its maintenance services. Prior to that, it was Jet Airways. Which other airlines are you planning to rope in as your customer?

A. SpiceJet, at present, has 42 aircraft and another 100 plus are expected to get added in the coming time, which is a very significant number. With SpiceJet, we recently signed a strategic partnership which will be mutually beneficial. Some time back, we did a major check for one of the planes of Jet Airways. We have provided such services in the past to GoAir which included an engine change and repair of landing gear, and we are looking forward to working with them again in future. This work is apart from servicing of planes of our parent company Air India and its other subsidiaries which have a large fleet together and are planning a further addition to it. Apart from Indian airlines, even the foreign carriers are showing a lot of interest in our services; considering the fact that we have a very large setup, best of facilities available in Asia and worldwide, plus at a very competitive cost. For example, recently we did the flap repair work of an airline after it was told by other MROs that it could not be repaired. So all in all, the response has been tremendous so far.

Q. What about business from Air Force? There have been plans to get MRO work from them...

A. There is an Air Force base in Nagpur. We are seeking to service IL76 and AN32 aircraft of the Air Force initially. In addition, slowly, we can expand and get more work from them in the future.

Q. Where do you see AIESL in the next five years? Will it able to charter a flight path of success for itself?

A. Though I don't have a number to give you about the plans in the five years from now, I can clearly say that our blueprint is well in place and we will soon be getting people in marketing and hiring department to expand our customer base. Our business plan is very clear as we want to become a self-sustained and profitable company in the next five years. We aim to earn around 40% of our revenue from the third-party servicing in near future, which is around Rs 130 crore of revenue in FY17; about double from the present.

Q. Please continue...

A. We will be marketing the concept of 'per hour of flight' which is very prominent in the foreign countries but has not yet caught up in the Indian aviation market. The primary aim of an airline is to serve passengers from point A to B and then further to point C. Maintenance and other work is not their core work and may seem to be a headache for them, as it requires setting up of an entire set up including engineers and other staff. The airlines as such will be more than happy to outsource this job (MRO) to us. As the name suggests, we will be charging the airline for per hour of flying plus other types of arrangements, depending on the work required. So, it is a win-win situation for both the parties.

Q. Do you think the new policy which aims at pushing regional connectivity in India helps in giving further impetus to MRO industry in India?

A. Regional connectivity is at the forefront of promoting aviation in India. More aircraft for regional connectivity means more opportunity as the planes will definitely require all kinds of maintenance and overhauling. Hence, definitely, I can sense a great business for MRO industry in general in the near future. The regional airlines, like the mainstream ones, will be able to save a great amount of their money which comes to about 20-25% if they service their planes in India instead of flying them abroad.

Q. As an MRO will you also be importing spare parts for the airlines?

A. No, we will like to avoid that as traditionally it is airlines which get the tax benefits for importing of spare parts, and hence, it is imported by them. But we will be helping them source it and facilitate.

Q. Tell me something about the engine facility to be set up by GE at Nagpur MRO and how important is its role in the overall servicing that you will be offering at the centre?

A. The engine facility set up of GEnx will be a money spinner for us. It is under construction and may get completed by November this year. A workshop for it will be set up and the complete service should get started by the year 2018.

Q. Tell us in brief about the MRO in Nagpur…

A. As part of commitment to the purchase of agreement for fleet, aircraft manufacturer invested about $100 million (which escalated to $107.4 million) towards the MRO facility including certain equipment/tooling required for aircraft maintenance and associated overhaul shops for maintenance of aircraft and components. An additional investment of at least $6 million has been made to make the facility functional. 50 acres of land has been acquired by Air India on a lease of 99 years from MADC in SEZ area near Nagpur airport to set up the facility. Boeing selected CBRE (CB Richard Ellis) as project management consultants (PMC) and M/S Larsen and Toubro as Design & Build (D&B) contractor. The MRO facility is designed for undertaking maintenance of any type and size of aircraft including A380. Each hangar can accommodate one wide body or three narrow-body aircraft at a time.

Q. What about the permissions? Are all such approvals and permissions in place?

A. Approval from aviation regulator Directorate General of Civil Aviation (DGCA) for C-checks (2,250 days inspection) on B777 series aircraft fitted with GE 90-100/115 engines have been granted in May 2015. Subsequent to it, D-check (3,000 days inspection) approval was granted in February 2016. Likewise, an internal audit has been carried out for Airbus family approval and approval is awaited for the application to DGCA for certification of A319/A320/A321 series aircraft fitted with CFM56-5b/V2500 A1 series engines up to 4A check.

Q. Manpower seems to be a major problem with AIESL. It is rumoured that not many engineers and others want to shift to Nagpur due to reported lack of social life as in a metro city. What is the management doing to tackle the issue so that it does not create a road block in the performance?

A. There have been no recruitment drives since past around a decade. So no new AMEs have been inducted. On the other hand, about 15-odd retirements are taking place every month out of total 300 AMEs all over the country. So, we are taking back the services of the good retired personnel on a contract basis. So, at present, we are just about managing the things. The situation may go out of hand if things don't improve in the next 3-4 years as then there will be a huge vacuum in the demand and supply. Further, the number of aircraft are increasing with each passing year.

So, at one point it may become a problem. Secondly, there are not enough engineers in the market with a licence as there is no provision in India to get typed licences like in the case of a pilot. To tackle the situation, we have started a training school in Trivandrum for third-party training of AMEs. However, still, a candidate takes around five years to get into the system. For example, the candidate has to first appear for a basic level examination. Then, he/she is put to type training followed again by an exam. If he/she passes the exam, then they are put under supervision. So it all takes about 5 years. Now there is a legal issue whether a third-party candidate can be absorbed into the company. For this, we are in talks with DGCA, which has shown some positive signs for it.

![submenu-img]() Meet IIT graduate who designed EVM, worked with Microsoft and Google, he works as…

Meet IIT graduate who designed EVM, worked with Microsoft and Google, he works as…![submenu-img]() Tata Motors planning Rs 8360 crore plant to make luxury cars in India, to set up…

Tata Motors planning Rs 8360 crore plant to make luxury cars in India, to set up…![submenu-img]() Meet man who has bought most expensive property on Bengaluru's 'Billionaire Street', Sudha Murty also...

Meet man who has bought most expensive property on Bengaluru's 'Billionaire Street', Sudha Murty also...![submenu-img]() Israel-Iran news live: Israel conducts air strike in Iran in retaliation to missile attack, says report

Israel-Iran news live: Israel conducts air strike in Iran in retaliation to missile attack, says report![submenu-img]() Neeru Bajwa says Punjabi film industry lacks professionalism: ‘We are not going anywhere until…’

Neeru Bajwa says Punjabi film industry lacks professionalism: ‘We are not going anywhere until…’![submenu-img]() DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'

DNA Verified: Is CAA an anti-Muslim law? Centre terms news report as 'misleading'![submenu-img]() DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message

DNA Verified: Lok Sabha Elections 2024 to be held on April 19? Know truth behind viral message![submenu-img]() DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here

DNA Verified: Modi govt giving students free laptops under 'One Student One Laptop' scheme? Know truth here![submenu-img]() DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar

DNA Verified: Shah Rukh Khan denies reports of his role in release of India's naval officers from Qatar![submenu-img]() DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth

DNA Verified: Is govt providing Rs 1.6 lakh benefit to girls under PM Ladli Laxmi Yojana? Know truth![submenu-img]() Remember Sana Saeed? SRK's daughter in Kuch Kuch Hota Hai, here's how she looks after 26 years, she's dating..

Remember Sana Saeed? SRK's daughter in Kuch Kuch Hota Hai, here's how she looks after 26 years, she's dating..![submenu-img]() In pics: Rajinikanth, Kamal Haasan, Mani Ratnam, Suriya attend S Shankar's daughter Aishwarya's star-studded wedding

In pics: Rajinikanth, Kamal Haasan, Mani Ratnam, Suriya attend S Shankar's daughter Aishwarya's star-studded wedding![submenu-img]() In pics: Sanya Malhotra attends opening of school for neurodivergent individuals to mark World Autism Month

In pics: Sanya Malhotra attends opening of school for neurodivergent individuals to mark World Autism Month![submenu-img]() Remember Jibraan Khan? Shah Rukh's son in Kabhi Khushi Kabhie Gham, who worked in Brahmastra; here’s how he looks now

Remember Jibraan Khan? Shah Rukh's son in Kabhi Khushi Kabhie Gham, who worked in Brahmastra; here’s how he looks now![submenu-img]() From Bade Miyan Chote Miyan to Aavesham: Indian movies to watch in theatres this weekend

From Bade Miyan Chote Miyan to Aavesham: Indian movies to watch in theatres this weekend ![submenu-img]() DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?

DNA Explainer: What is cloud seeding which is blamed for wreaking havoc in Dubai?![submenu-img]() DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?

DNA Explainer: What is Israel's Arrow-3 defence system used to intercept Iran's missile attack?![submenu-img]() DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence

DNA Explainer: How Iranian projectiles failed to breach iron-clad Israeli air defence![submenu-img]() DNA Explainer: What is India's stand amid Iran-Israel conflict?

DNA Explainer: What is India's stand amid Iran-Israel conflict?![submenu-img]() DNA Explainer: Why Iran attacked Israel with hundreds of drones, missiles

DNA Explainer: Why Iran attacked Israel with hundreds of drones, missiles![submenu-img]() Neeru Bajwa says Punjabi film industry lacks professionalism: ‘We are not going anywhere until…’

Neeru Bajwa says Punjabi film industry lacks professionalism: ‘We are not going anywhere until…’![submenu-img]() Meet actress who married a CM against her family's wishes, became his second wife, her net worth is..

Meet actress who married a CM against her family's wishes, became his second wife, her net worth is..![submenu-img]() Meet India's richest actress, who started career with two flops, was removed from multiple films, is now worth...

Meet India's richest actress, who started career with two flops, was removed from multiple films, is now worth...![submenu-img]() Meet hit director's niece, who was bullied for 15 years, Bollywood debut flopped, will now star in Rs 200 crore project

Meet hit director's niece, who was bullied for 15 years, Bollywood debut flopped, will now star in Rs 200 crore project![submenu-img]() Abhilash Thapliyal discusses Maidaan, reveals he lost chance to play PK Banerjee in Ajay Devgn's film for this reason

Abhilash Thapliyal discusses Maidaan, reveals he lost chance to play PK Banerjee in Ajay Devgn's film for this reason![submenu-img]() IPL 2024: Ashutosh Sharma's heroics in vain as Mumbai Indians return to winning ways with 9-run victory over PBKS

IPL 2024: Ashutosh Sharma's heroics in vain as Mumbai Indians return to winning ways with 9-run victory over PBKS![submenu-img]() LSG vs CSK, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report

LSG vs CSK, IPL 2024: Predicted playing XI, live streaming details, weather and pitch report![submenu-img]() LSG vs CSK IPL 2024 Dream11 prediction: Fantasy cricket tips for Lucknow Super Giants vs Chennai Super Kings

LSG vs CSK IPL 2024 Dream11 prediction: Fantasy cricket tips for Lucknow Super Giants vs Chennai Super Kings![submenu-img]() PBKS vs MI IPL 2024: Rohit Sharma equals MS Dhoni's massive record, becomes 2nd player to....

PBKS vs MI IPL 2024: Rohit Sharma equals MS Dhoni's massive record, becomes 2nd player to....![submenu-img]() Major setback for CSK as star player ruled out of IPL 2024, replacement announced

Major setback for CSK as star player ruled out of IPL 2024, replacement announced![submenu-img]() Canada's biggest heist: Two Indian-origin men among six arrested for Rs 1300 crore cash, gold theft

Canada's biggest heist: Two Indian-origin men among six arrested for Rs 1300 crore cash, gold theft![submenu-img]() Donuru Ananya Reddy, who secured AIR 3 in UPSC CSE 2023, calls Virat Kohli her inspiration, says…

Donuru Ananya Reddy, who secured AIR 3 in UPSC CSE 2023, calls Virat Kohli her inspiration, says…![submenu-img]() Nestle getting children addicted to sugar, Cerelac contains 3 grams of sugar per serving in India but not in…

Nestle getting children addicted to sugar, Cerelac contains 3 grams of sugar per serving in India but not in…![submenu-img]() Viral video: Woman enters crowded Delhi bus wearing bikini, makes obscene gesture at passenger, watch

Viral video: Woman enters crowded Delhi bus wearing bikini, makes obscene gesture at passenger, watch![submenu-img]() This Swiss Alps wedding outshine Mukesh Ambani's son Anant Ambani's Jamnagar pre-wedding gala

This Swiss Alps wedding outshine Mukesh Ambani's son Anant Ambani's Jamnagar pre-wedding gala

)

)

)

)

)

)

)