It’s simply called, ‘Khadi Denim’, but Delhi-based label 11.11’s regular blue jeans is a special garment. Made from an indigenous variety of cotton called kala cotton that is cultivated pesticide-free in Kutch, it is hand-spun in Saurashtra (Gujarat) and sent to Auroville

(Puducherry) for dyeing using natural Indigo, before going back to Saurashtra where it is woven, and finally to Delhi, where it is stitched by hand.

Designers Shani Himanshu and Mia Morikawa and co-founders of the label, launched Khadi Denim five years ago. “Kala cotton doesn’t need irrigation or cultivation and relies entirely on rainfall. It is sowed after the first rainfall and takes two more rainfalls to grow. The crop yields short-staple yarn, which absorbs colour beautifully and is transformed during dyeing,” says 38-year-old Himanshu. Short staple cotton yields an uneven yarn, one of the reasons for its decline in the mainstream market. The yarn, however, is strong, coarse and stretchable. “As time passes, the hand-woven textile made of this yarn takes the shape of the body and becomes like a second skin. As the fabric fades, it softens the hand stitches, which becomes clear revealing its handmade character,” adds Himanshu.

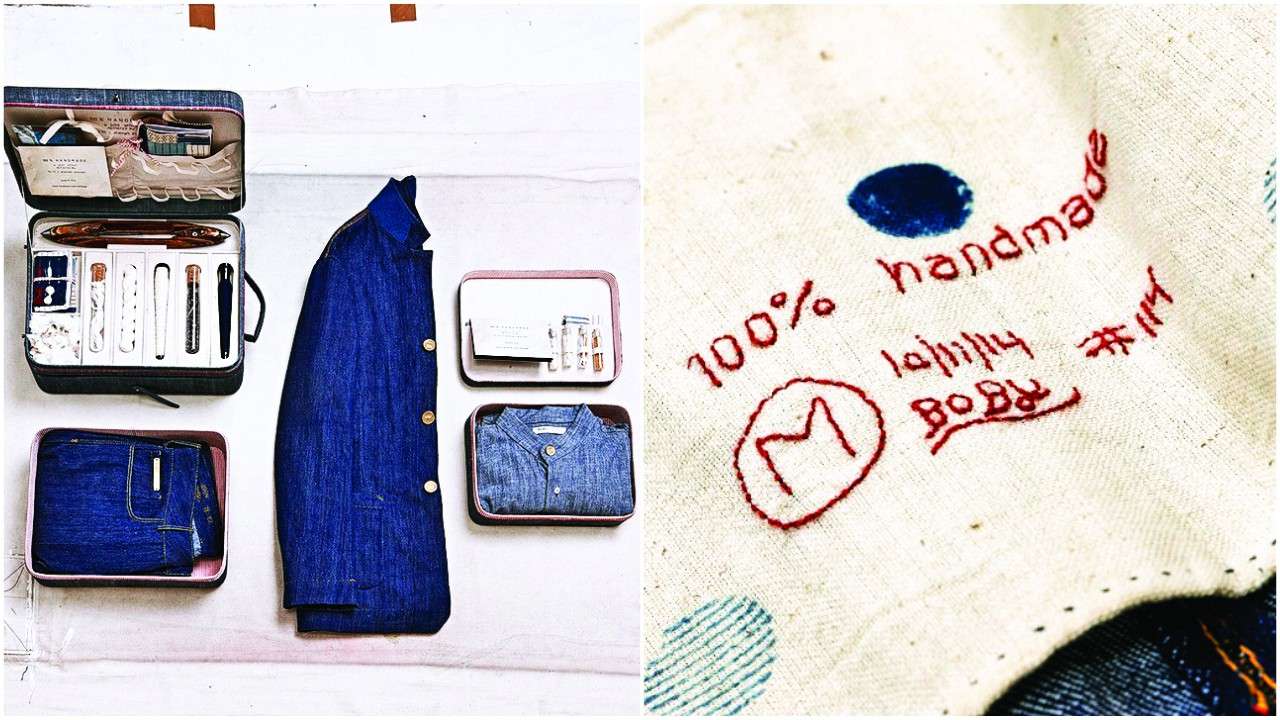

Khadi Denim makes its buttons from recycled brass coins of 1, 5 and 20 paisa denomination. To ensure the end product is able to tell its story, it’s packed in a ‘route box’ which contains several glass vials filled with bits of hand-spun yarn, indigo, plus tags, a booklet on Khadi Denim and a notebook made from recycled waste generated during the manufacturing process.

Khadi Denim isn’t cheap — about `30,000, without the route box. Himanshu says that’s not expensive, given that it’s 100 per cent handmade. Why is the same question not asked of industrial products which should cost less since they are mass manufactured, he asks. “We invest several months to create a product whereas, in mass production industry, the maximum time involved is 60 days. In our work, everything is done manually by artisans across regions and we pay them fairly. We also sell only a limited number; so there is an attached cost at the retailer’s end. The price is not that much compared to its value,” says Himanshu.

11.11 is also involved at every stage of production from seed to stitch. The label focuses on training people to hand-stitch a complete product as opposed to garment factories where several “unskilled” workers work on different parts of a garment – some who only do the embroidery and others who do the finishing.

“We train people for three-four months to construct a garment and it takes about 7-10 days to stitch it. The beauty of the process is that they

acquire the knowledge of making the garment,” says Himanshu, citing the example of Italian Sartos, meaning tailors or dressmakers. “An Italian Sarto will hand-construct the whole jacket before stitching it. This is the purest way of doing it,” he adds.

Besides, the person who stitches the Khadi Denim also signs and dates it. The label has also worked on traceability, with a unique code for each garment. “The code allows it to be traced backward — when was it cut, who stitched it, where did the fabric come from, the measurements, etc. At present, you can access this information by asking us over email but in future, we plan to put all the information online.”

But what about carbon footprint? Surely Khadi Denim’s multi-centre production must take away from its green credentials? Himanshu has a counter argument. “We send yarn to Auroville because we don’t have a choice. The facility is not there in Gujarat and we don’t want our yarn to be dyed chemically. We rely on public transport. The plane would anyway fly to

Puducherry, Gujarat or Delhi, it isn’t as if I am sending the yarn by private cargo.”